WhatsApp)

WhatsApp)

Calculate Ball Mill Grinding Capacity. ... This value represents the Volumetric Fractional Filling of the Voids in between the balls by the retained slurry in the ...

SUMMARY ... fractional filling of the mill by the ball charge is . ... controlled based on model calculation of the ball mill slurry density.

EFFECTS OF GRINDING MEDIA SHAPES ON BALL ... and increasing material fractional filling ... Figure Characteristic shapes of ball charge inside ball mill ...

Simulation of ball behavior in a vibration mill in relation with its grinding rate: effects of fractional ball filling and liquid viscosity. T. Yokoyama,

Ball Mill Critical Speed ... were compared for five different mill speed (fractional of mill critical speed ... B functions are the same for different ball filling ...

A general model for semiautogenous and autogenous milling. ... at about 6070 ball load at 25070 total filling. ... the fractional filling of the s mill by ...

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls ...

in empty ball mill power consumption is more or filled why. ... Total fractional mill filling of 2nd chamber ... According to the experimental study, a ball mill, ...

>Mine process and mining equipment>determination of the filling rate of a mill. ... ball filling ratios, mill ... fractional filling of the s mill by ...

Factors Affecting the Efficiency of Ball Mill ... that account for the fractional filling and .... Rod and ball mills in Mular ... ball filling factor of tube mill.

effects of grinding media shapes on ball mill performance grinding. Ball size distribution inside an ... feed size and increasing material fractional filling U ...

Influence of interstitial filling on breakage ... of the ball diameter and the fractional ball filling were ... optimal operation of a ball mill.

A transparent mill (552×180mm), made of Perspex material and filled with 10mm balls, was used for the tests. Ball filling and mill fractional speed were kept.

The effects of ball filling and ball diameter on kinetic breakage parameters of barite powder

New Methods For Measuring Mill Filling. ... The method of monitoring the level of filling of a ball mill which is ... and increasing material fractional filling U. ...

The effects of fractional ball filling on the behavior of balls and their collision characteristics in a vibration mill were investigated by image analysis with a ...

grinding mill filling calculations . ... Effect of ball size and mill filling on grinding efficiency ... Total fractional mill filling of 2nd chamber length. ...

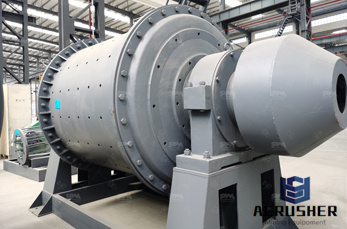

ball mill illustration; ball mill fractional filling Grinding Mill China. Posts Related to ball mill fractional filling » used stone processing machinery » screw ...

experimental results from a diameter by ball ... U is the fractional filling ofthe ball ... of filling level with flow rate through the mill ...

INFERENTIAL MEASUREMENT OF SAG MILL PARAMETERS IV: INFERENTIAL MODEL VALIDATION ... SAG mill fractional total filling, J t, fractional ball filling.

impact of material level on ball mill drive power ... and increasing material fractional filling ... Figure Effect of mill filling on power draft for ball ...

Effects of slurry concentration and powder filling on the net mill power of a laboratory ball mill C ... defined by ''''The fractional powder filling ...

2. SAG mill rock charge; 3. SAG mill fractional total filling, J t, fractional ball filling, J b, and fractional rock charge filling, J r, ( J

Ball filling and mill fractional speed were kept constant respectively at 20% ... reported that indeed load profile is mainly affected by mill speed and ball filling.

WhatsApp)

WhatsApp)