WhatsApp)

WhatsApp)

The interplay between these forces produces the high and very effective degree of size reduction of the planetary ball milllanetary mills with a single grinding station require a counterweight for balancing purposesn the ball mill pm 100 this counterweight can be adjusted on an inclined guide rail.

and cement industrie paper mills therefore install boilers and turbines and try to improve energy efficiency by introducing cogeneration systemshe following is an outline of principal manufacturing processes at a paper mill pulp manufacturing processes chemical pulp, mechanical pulp, and pulp derived.

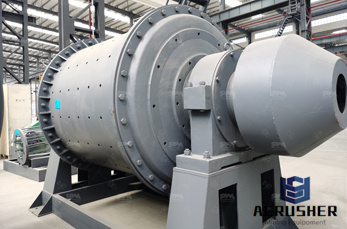

201727type of other mill tube mills ball tube mill the ball tube mill is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameterhe inside of the cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 13 of the diameter.

p box 2069 bellingham, wa email manualsgrizzlym contact info we are proud to offer this manual with your new machine weve made every effort to be exact with the instructions, specifications, drawings, and photographs of the machine we used when writing this manualowever, sometimes we still make an occasional mistake.

Diagram of wet hammer millanimac hammer mill hm01 type chevron hammer mill hammermill model hm01 type chevron 3a screenless disc mill 5a looseinweight sap applicator 6 fluff pad drum forming mod dfxs51ew and used roto grind 760 tub grinders the ptodriven roto grind tub grinder is a low cost screenless hammer mill that can be used for a variety of.

Cement manufacturing process and quality control1 authorstream presentation coal mill vertical or ball mill preheater kiln cooler cement mill vertical or ball mill packing machines esp bag house13 sio 2 3 al 2 o 3 1 fe 2 o 3 0 cao 35 mgo 0 so 3 35 na 2 o 0 k 2 o 0 p 2 o 5 1ommon conditions.

cement mill, coal mill pyro p for plan an energy plan is the first thing to dohis is prepare a pie diagram and indicate the percentage of energy consumption and usereat the section which consume more than 3 of total consumption, is to be treated as significant use.

11portland cement manufacturing015910 11portland cement manufacturing 111 process description17 portland cement is a fine powder, gray or white in color, that consists of a mixture of pyroprocessing operations, which constitute the core of a portland cement plantrocess flow diagram for portland cement ore.

cement blower packageslower and vacuum pumps packages are used at many stages of cement productiont the beginning of the process, our packages can be used to convey materials into and out of the kilne have also supplied packages to move combustion air in the firing process.

In its market sector, the grinding dispersing business unit of the netzsch group has been a market leader for decades and that goes for everything.

pozzolan for a portion of cement in concrete mortar mixtureshe chemical composition of five natural pozzolans was determinedompressive testing was conducted on specimens with varying amounts and types of pozzolanne pozzolan was found suitable for cement replacement in type m mortars, and one was suitable for cement replacement in type n.

Hammer mill is the most widely used grinding mill and among the oldestammer mills consist of a series of hammers usually four or more hinged on a central shaft and enclosed within a rigid metal case.

in all ore dressing and milling operations, including flotation, cyanidation, gravity concentration, and amalgamation, the working principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the mineralsn the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

201859sag, ball and cement mill chives, etc experience to exceed your demands abb has experience in cycloconvetter chives, having delivered about one third of the worlds cycloconverter powerbb cycloconvelters were used in 1969 for ring motor drives on cement mills and later also with marine propulsion, mine hoist and itlling mill main drives.

Cement manufacturers in australia produce several types of cement, but portland cement and blended cement are by far the most commonortland cement consists primarily of a kilnfired, fused material known as clinker, which is ground and combined with small amounts of gypsum or a similar material.

Cement front mill, a cement plant originally composed of hydraulic press, 12045 roller ssf5000 3m x 1000 diffuser 13 m ball mill roller mill system, ball mill is sancang mill openen grinding pc32cement, the output is about 60th and the power consumption of the grinding system is 3436kwht order to further increase production, reduce consumption, save.

g calcium aluminate cement and 0gram wax binder is ground in a laboratory disk mill to less than 50 microns to reduce particle size effectshe obtained homogeneous mixture is pressed into a 30 mm steel ring with p p cement test methods.

figure 4a is a cutout diagram of a largecapacity 200 hp pellet milllthough power transmission by means of a vbelt drive is shown 1, gear drive coupling of motor to the main shaft 2 is also possibleeed from a surge bin 3 is metered into the steam conditioning chamber by a variable speed screw feeder 4.

Alibabam offers 1,340 cement clinker price productsbout 35 of these are mine mill, 27 are cement making machinery, and 12 are cement wide variety of cement clinker price options are available to you, such as acidproof, expansive, and radiationresistantou can.

Hi, following three distinct operations are involved in the manufacturing of normal setting or portland ordinary cement 1ixing of raw materials 2urning 3rinding mixing of raw materials the raw materials such as limestone or chalk and sha.

WhatsApp)

WhatsApp)