WhatsApp)

WhatsApp)

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E. Schilling, M. Yang UNION PROCESS INC. Akron, Ohio Presented by Robert "Bob" Schilling Presented at the .

A cement mill (or finish mill in ... Ball mills are normally operated at around 75% of critical speed, so a mill ... The efficiency of the early stages of grinding in ...

Paul O Abbé Equipment Company is a manufacturer New Steel Ball Mills and Milling Equipment. Call or request a quote to get started.

Derivation of critical speed of grinding mill – The QA wiki. What is critical speed of a SAG mill? The critical . is two latticetype ball mill. The materials ...

Ball Mill manufacturers in Mill critical speed design in India India ball mill manufacturers provides you the ball mill and critical speed for ...

Jun 19, 2015· https:// Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill .

Introduction Welcome to the Ticonderoga Branch! This site examines the history of the Delaware Hudson Railroad''s branch lines to Baldwin Dock and ...

critical speed ball mill wholesale, buy critical speed ball mill from 422 critical speed ball mill suppliers from China.

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... The critical speed of the mill, ... is defined as the speed at which a single ball will just remain against the wall ...

Are you carving large 3D contours or carvings ? You''ll want a ball nose bit that is appropriately sized for the level of detail in your model.

Intro: Use a Treadmill DC Drive Motor and PWM Speed Controller for Powering Tools. Power tools such as Metal cutting mills and lathes, Drill presses, bandsaws ...

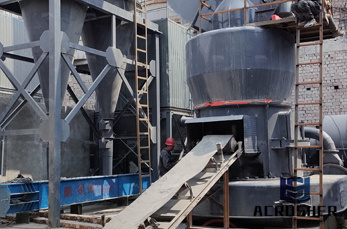

critical speed ball mill. critical speed ball mill The following is the latest product, the specific details click on image consulting product, you can get 50% off ...

/S"1 International Mining Congress and Exhibition of TurkeyIMCET 2003, (c 2003. ISBN The Effect of Fraction of Mill Critical Speed on Kinetic Breakage ...

Running the correct PROMAX solid carbide end mills at the proper speeds and feeds is critical to obtaining the best production times and tool life.

The Critical Speed is used for the determination of ball mill ideal operating speed. But for comparison, rod mills would operate between 50% to 95% of the critical speed.

TheINQUIRER publishes daily news, reviews on the latest gadgets and devices, and INQdepth articles for tech buffs and hobbyists.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Critical Speed of Ball Mill For a ball mill, it does not have a constant critical speed, because of the centrifugalization of the steel balls is different accor

Thomson has a long history of manufacturing quality, strength, and expertise in all of its ball lead screw products.

Ball Mill Operating Speed Mechanical Operations . The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm ...

End mills (middle row in image) are those tools which have cutting teeth at one end, as well as on the sides. The words end mill are generally used to refer to flat ...

34 The European Journal of Mineral Processing and Environmental Protection Vol. 2, No. 1,, 2002, pp. 3439 Technical Note Why is the Bond Ball Mill ...

Critical Speed Of Ball Mill, Wholesale Various High Quality Critical Speed Of Ball Mill Products from Global Critical Speed Of Ball Mill Suppliers and Critical Speed ...

WhatsApp)

WhatsApp)