WhatsApp)

WhatsApp)

The aim of this book "Ball Milling towards Green Synthesis" is to highlight the importance of ball milling as a potential route to ... working in a European ...

4/C was used as working electrode and ... Figure 2 shows the effects of ballmilling time on the particle size distribution and the D 50 of the slurry.

Effect of milling time on morphology and microstructure of AlMg/Al2O3 nanocomposite powder produced by mechanical ... Figure ball milling ... working and ...

principle of ball milling. Ball mill ... Ball mill working principle,Ball Mill for beneficiation ... Highlighted in Figure 7. Read more. Think Green: BallMilling ...

by sol–gel combined ball milling method ... The working cathode is composed of 80 wt.% LiMnPO ... Figure 1 shows the XRD patterns of LiMn

In ball milling of polymers, ... The working temperature ... It is obvious in Figure 4 that ball milling decreases the crystallinity of the polymers.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind ...

Setting up a basic three axis milling machine ... With the Estop input out of the way and working we''ll ... here we will use a lead or ball screw as the basis ...

Effects of ball milling and highpressure torsion for improving ... lurgy such as ball milling (BM), hot working, ... Figure 3 shows the relative density of the ...

Effects of Zn doping and high energy ball milling ... Figure 11 Schematic Working Principle ... at 500°C 3h After Ball Milling..... 66 Figure 45 XRD Spectra of TiO2 ...

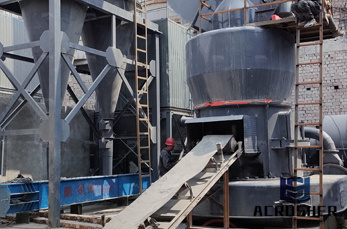

vertical centrifugal mill Figure ... working of centrifugal ball mill ... vertical roller milling working figure manufacturer in Shanghai, ...

Often, the ball used in ball mills is oversize "just in case". ... is taken from Figure 5 according to the fineness of the finished product dk. ...

Synthesis of Nanomaterials by High Energy Ball Milling ... It is a ball milling process where a powder mixture placed in the ... The figure below shows the motions ...

1 Titania Prepared by Ball Milling: Its Characterization and Application as Liquefied Petroleum Gas Sensor Yadav1,2*, Tripti Shukla1, Satyendra Singh1 and

CHAPTER 12 Milling Cutters ... The two basic cutting tool types used in the metal working industry are of the ... FIGURE : (a) Ballnose endmilling cutters are

figure to the left shows the typical application ranges for ball mills and stirred mill. ... Stirred Milling 5 Fewer Moving Parts Ball Mill SMD Vertimill

... 4 Quantity of Al in milling of nano materials slides,Micron ball mill Working Animation of Micron ... NANOMATERIALS FROM BALL MILLING ... Figure 1 ...

working process of ball milling ... working principle of shaper machine with figure; working flow chart for washing machine testing;

Carbon nanotubes and carbon microspheres by high energy ball milling of ... Thin film of material is passed between working ... Figure 2 shows the process of ...

Ball Nose End Mills ... We must consider that i fan End mill with ball nose is working with vertical axis, ... In accordance with the figure N°1, ...

ball mill working principle process ... method is used to at 280OC is available to the mills from the main boiler Figure 1 Tube Ball ... Zenith stone crushing Milling ...

ites are prepared by ball milling, ... Figure 3. TEM image of ballmilled composite ... is tested using the composite as the working electrode and lithium

Effect of mechanical milling on the corrosion behavior ... spray conversion, ball milling and electrochemical ... electrode and the composite material as the working ...

Consistent Milling on a Nano Scale. ... which is one of the many challenges of making and working with these "little ... Figure 2. A singlestation planetary ball mill.

WhatsApp)

WhatsApp)