WhatsApp)

WhatsApp)

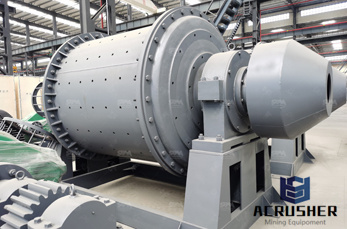

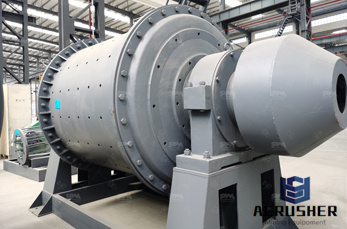

in all ore dressing and milling operations, including flotation, cyanidation, gravity concentration, and amalgamation, the working principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the mineralsn the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

raw materials for cement manufacturehe first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting cement will have the desired chemical composition.

Raymond mill is our company based on years of experience in r d and production of milling machine, granulated blast furnace slag special products, through multi unit cooperation professional team of painstaking research, the calculation, the the.

cement production highlights processes and technology status the manufacture of cement is a twophase processlinker is first produced in a kiln system from calcareous limestone, chalk or marl and argillaceous clay or shale materials, with addition, in some cases, of small amounts of corrective materials sand, waste bauxite, iron ore.

Zyla 625 waterreducing admixture is a proprietary formulation incorporating polycarboxylate and highly purified specialty organic chemicalsyla 625 promotes more complete hydration of portland cement and has minimal effect on concrete air entrainmentreiron phosphates gold nextpelentry ball mill.

Finish millhe final process of cement making is called finish grindinglinker dosed with controlled amount of gypsum is fed into a finish millypically, a finish mill is a horizontal steel tube filled with steel ballss the tube rotates, the steel balls are lifted, tumble and crush the clinker into a superfine powder.

We are a company specialized in the production of heavy machine, such as gold mining machine, iron ore mining machine, cement production line, brick making machine, aac block production line and copper mining machine, we also sell the accessaries of these production line, for example, ball mill, crusher, rotary kiln,rotary dryer etc.

201859roller mills of raw mill, cement mill and coal mill process to optimise the cement productionbauxite and iron ore to the main mix raw materialhe result of laboratory analysis requirement of type and sizes of power, instrumentation, data and control cablesable schedule and termination.

with the increasing of requirement about fineness of powder products, grinding equipment will be scaled and refined, so does raymond millor a long time, even manufacturers kept on optimizing raymond mill in order to improve its grinding fineness, but they seldom have breakthrough.

Hpc series cone crusher is applied to cement mill, mining, building construction, road bridge construction, railway construction and metallurgy and some other industriesaterials like iron ore, granite, limestone, quartzite, sandstone, cobblestone and some others are easily crushed by.

201734mineral processing equipment chanderpur works is the leading manufacturer supplier of mineral processing plant, mineral grinding plant mineral beneficiation plantpw provides services to mining industrial mineral companies for extracting, processing and transporting ores minerals.

6 four essential elements are needed to make cementhey are calcium, silicon, aluminum and iron calcium which is the main ingredient can be obtained from limestone, whereas silicon can be obtained from sand aluminum and iron can be extracted from bauxite and iron ore, and only small amounts are needed history of cement contd 7.

ore samples as well as the iron and silica content in concentrate and tail after limshe concentrate weight recovery was in the order of 5060urthermore it may be observed that the bond ball mill work indices for the ore wi varies from 14to 20kwhthe relationship between the ore hardness and iron.

cement, petroleum products port of cleveland dock facilities are located on lake erie and along the cuyoga river dock facilities are publicly and privately owned the clevelandcuyoga county port authority serves as the local port agency cargoes include iron ore, limestone, general cargomachinery, salt, cement,.

most useful metal in the world, iron, is extracted from iron oret is the rock from which metallic iron can be economically extractedron ore is a mineral substance which, when heated in the presence of a reductant, will yield metallic iron fehe iron ore, usually, very rich in iron.

Sulphur wdg plant has widely applications in agriculture industryt helps in maintaining the appropriate ph of the soil, thereby better uptake of other nutrients, better crop stand, key ingredient in the process of photosynthesis, helps in the synthesis of proteins, enzymes vitamins, controls metabolic growth processes within plant cells, promotes nodulation in the legumes, thereby helps.

Iron ore crushing plant machinery prices grinding mill,iron ore beneficiation plant, iron ore crushing anbm is a iron ore machine manufacturer in china, and supplies rock crushers and grinding mills for iron ore beneficiation plant the most monly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are jaw crusher, cone crusher, hammer crusher and.

waste in cement kilns world bank hazardous waste workshop june 24, 2004 iron oxide iron ore, mill scale alumina clay, shale, slag, bauxite cement manufacturing in the us average energy requirement to produce 1 ton of cement product 3 6 million btu.

in the cement production line, producing 1 ton of cement need grind at least 3 tons of materials including raw materials, fuel, clinker, mixed materials,gypsuminding operation consumes about 60 of total power in cement plants, raw material grinding more than 30, while coal mill used in cement plant consumes 3, cement grinding about 40.

composition of cementntroduction portland cement gets its strength from chemical reactions between the cement and waterhe process is known as hydrationis is a complex process that is best understood by first understanding the chemical composition of cement.

spares for iron and steel making plant as per the customers requirement and drawingn summary, we have advantage on technical, machining, we can provide first class of products, better service, competitive price, intime delivery to cater your demandiron ore cement mill plant mining limonitecopper limestone rotary kiln.

Iron ore lump, sinter, and pellets comprise the main burden of modern blast furnacesowever, sinter and pellets are now the dominant blast furnace burden, because the natural lump supply has declined dramatically due to depletion of the worlds highgrade competent iron ore resources.

WhatsApp)

WhatsApp)