WhatsApp)

WhatsApp)

Silicon carbide was produced by milling and mixing waste glass and graphite powder in different grinding mills planetary mill and ring millhe samples were then heat treated at 700 c for 1 hour soaking timewo types of characterization procedures were completed to determine the properties and microstructure of silicon carbide.

the mill also includes the processes of attrition and impact, although these actions are limited if the material is easily reduced by cutting and the screen limiting discharge has large perforationshe mill consists of a rotating shaft with four attached parallel knives and a screen occupying one fourth of the 360 degree rotation.

Using the bond index test procedures it is possible to calculate crushing abrasion behavior of mineral sampleshis knowledge is essential to define the required ball mill layout and production capacitythe grinding jar for the bond index rod mill is 12 x 24 in size and has a waveshaped design.

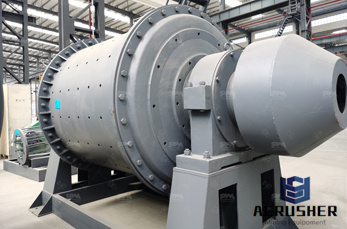

these large coal crushing drive systems are usually rotated by motordriven gearing typical application consists of a motordriven primary singlestage reducer that, through a flexible coupling, drives a large open pinion which in turn, meshes with a large ball mill ring girth gear that is attached directly to the ball mill.

Ball mill show the picture of a processed barytess a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

effects of excess sulfur on cement production in order to determine the effects of increasing the sulfur content in the clinker on the overall cement producing process, a baseline was established on an existing finish mill systemhe existing ball.

longemont tech coltds a joint stock company engaged in the research, manufacturing and selling of heavy mining machinery, such as crushers, powder makers, sand makers and construction machineryur headquarters is located in shanghai, chinas most developed city.

Grinding calculationball mill designrinding calculationball mill powerrinding calculationproduction prediction at different finenesspi calculations new addition to courseement mill ball mill water spray calculation new addition to courseection iv applications of measurements and calculationseasurement system analysis.

Mill diameter, mill length, grates openings, and pebble ports size the power equation is also function of all the operational variables selected for this studyhe applied force is a function of the mass inside the mill and it is composed of balls, ore and waterhe ball charge is a function of the bulk fraction of the sag mill volume jb.

Cement manufacturing by wet process the raw materials are calcareous materials like limestone or chalk and argillaceous material such as shale or clay burning this composition in a kiln at a temperature of about 1300 to 1500c cement manufacturing a wet process with the flow diagram in the wet process rotary kiln maintenance procedures.

The process of cement production involves complicated procedures and machinesmong the entire process of cement production, the crusher is used to turn bigsize stones to small particles, which paves the way for next stepsbms pew series jaw crusher is suitable for primary crushing, even in the most challenging conditions.

manufacturing of cement involves various raw materials and processesach process is explained chemical reactions for manufacture of portland cementement is a greenish grey colored powder, made of calcined mixtures of clay and limestonehen mixed with water becomes a hard and strong building.

Efficient ball mill procedure in the green asymmetric aldol reaction, efficient ballmill procedure in the green asymmetric aldol reaction the organocatalytic activity of sprolinebased dipeptides 1ac has been evaluated in the asymmetric aldol reaction between representative ketones with vari.

the emission limit values shall be set by national authorities based on best available techniques for the relevant industrial sectorhe aim of this document is to provide background information on the cement industry and cement manufacturing technology, and to determine best available techniques for the installations for production of cement.

201425cement rotary kiln questions answers question1 what is the maximum continuous shell temperature a kiln stands without permanent damage to the shell answer1 the maximum recommended kiln shell temperature varies by plant, by country and by kiln manufacturer, despite the fact that most kiln shells are made of low alloy carbon steel.

the evaluation of grinding aid ga effect on clinker processing in laboratory grinding mills is relatively simpleet, the results obtained cannot be directly transposed to industrial mills, given the fundamentally different operational modes and grinding parametershis paper seeks to evaluate the scale effect by comparing the results obtained from a closedcircuit tube mill operating at.

Standard operating procedure of cad mill used in granulation of tabletsearn moreall mill relining standard operating procedure pdf freall mill relining standard operating procedure pdf freed trouble free operation processes within the cement f mill lining and the balls themselves learn moretandard operating procedures.

compartmenthe fine ground cement leaves the mill by a discharge diaphragm also in christian pfeiffer monobloc design and is fed to the separator circuit by a bucket elevatorhe two compartmens of the mill have a ball filling of about 28, whereby the first chamber is filled with grinding media of 90 to 60 mm, the second chamber.

the paper presents the design procedure of a modelbased control algorithm for the regulation of tailings and product flowrates in a cement millhe control variables are the feeding rate and the classifier speedxperimental results of a fullscale industrial application are reported and discussed with a view to the control of the fineness of the cement.

Mill settings and reabsorption raymond mill raymond mill in pakistan raymond mill for sale raymond mill supplier wet ball mill dry ball mill batch ball mill cement ball mill grinding mill mill grinder ball mill grinder cement powder mill fines difference between raymond mill and ball mill stone crusher machine.

make a ball mill in 5 minutes this is for all the pyro nuts that i came across on instructableshis can be used to grind chemicals to a very fine grain or to polish rockski says a ball mill is a type of grinder used to grind materials into extremely fine powder for use i.

field sampling and testing manual esting procedures or all tests ntentionally left blank revised procedures page 1 of 2 testing procedures for all tests nd t 119 slump of hydraulic cement concrete d t 121 density unit weight, yield, and air content gravimetric of concrete.

WhatsApp)

WhatsApp)