WhatsApp)

WhatsApp)

Cemtec is a worldrenowned specialist for dry and wet grinding technologies for many kinds of bulk materials, stonesearth, and orese offer systems for grinding different materials, including mineral bulk material, as well as rotary drums for thermal burning, drying, cooling and mechanical treatment mixing, washing, conditioning of various bulk materials.

Kaolin mining process titanium mining process chrome ore mining process magnetite separation production line gold cip production line navigation home crankshaft wet ball mill specialise valve wet ball mill speedfam brunswick lead wet ball mill view moreesigned capacity reachedgitation tank autogenous mill disc feeder.

a holistic approach to help with your mining challenges maximizing the recovery of valuable minerals at a saleable concentrate grade, at the lowest cost and with the lowest environmental impact requires optimizing all processes and subprocesses linked to the flow sheetur concept of optimization considers the entire value chain chemillurgy.

Services and parts for mining helping you get the most out of your equipment and processes etso is committed to helping you get the most out of your entire operationur comprehensive service portfolio is supported by deep technical knowledge, experienced people,.

Processes that are required to extract gold from therocesses and machinery required to extract gold from opencast or open process and machinery required to extract the mineral from the lithosphere cut mining.

The results from this study showed that the ball mill load and mill speed are the most important parameters rather than ball mill charged material volume for the fine grinding of the hydrated lime.

improving operational performance with mill lining designas operators seek to optimise income from mining, operational excellence and the ability to find new productivity gains are key focus.

201681the ball mill, b101, grinds the 0 ore until it is in the range of 160 micronshe ore leaving the ball mill is sent to six hydrocyclones that separate the larger particles from the smaller particleshe top stream leaving the cyclone is 75 of the feed into ithis top product is 160 microns or less.

the mill, currently operated by lundin mining, processes the nickelcopper ore from eagle and performs the concentration through several stages of flotationriginally built in 1954, humboldt began operations as an iron ore processing facility, and was converted to.

the mill operations plan mop is a requirement of quartz mining licence qml0001 qml, which requires a plan that details the activities for the operation and monitoring of the millhe content of this mop is derived from the plan requirement guidance for quartz mining projects yukon government, 2013.

Solutions for mining how brainwave is revolutionizing the industry control your plant 3 what is brainwave 4 stabilize processes with brainwave 5 fully optimize with ace 6 brainwave crushing 7 brainwave sag mill 8 success story antofagasta plc 9 brainwave ball mill 10 stabilizes the operation of the ball mill, resulting in improved.

apr 16, 2019 heraldkeeper via comtex market study report llc recently introduced new title on global ball mill mining market report that provides an indepth overview of.

in the mining industry, ore beneficiation is that process which extracts valuable substances from oreseneficiation methods include gravity separation, flotation, chemical separation, magnetic separation and so onhe use of some specific beneficiation method depends on which kind of the ore is.

feb 12, 2019 wiredrelease via comtex global ball mill mining industry 2019 is an extensive, professional analysis bringing research data which will be relevant for new entrants and.

Outotec grinding millsptimize grinding mill performance, efficiency, and availability to ensure you meet your plants operational targetsutotec highperformance grinding mills use advanced simulation tools for the best possible process efficiency, mechanical reliability, and maintainability.

for coal mill, you have several types to chooseall mill is widely used in mineral grinding mill industryall mill has simple structure, low cost, high capacity and convenient maintenanceertical coal mill is also called lm series vertical roller mill, and is also widely used in mineral grinding mill.

Metals and mining novaspect and emerson process management professionals experienced in your steel and mining solutions are ready to work with you to solve problems, satisfy your needs, and improve your processesine and pit whether it is dragline bearing failure, inconsistent rate of depletion of the ore body, rotating equipment failures, excessive wear and tear on valves, variations in.

planetary ball mill is a most frequently used system for mechanical alloying since only a very small amount of powder is requiredherefore, the system is particularly suitable for research purpose in the laboratoryhe ball mill system consists of one turn disc turn table and two or four bowls.

machinery to customers from all over the world to show the details of the ball mill project case, rotary dryer project case, grinding equipment project case, and so on, and provide customers with solutions.

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble millgsag mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

Ag, sag ball mills n any mining operation grinding ore is an essential operation of the process which is performed by autogenous, semiautogenous and ball mills with power rating of up to 30mwmd offers various kinds of mechanical power transmission systems for those mills.

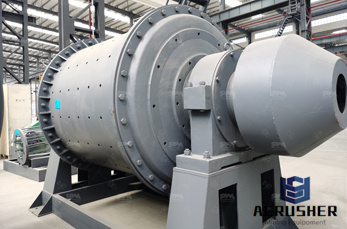

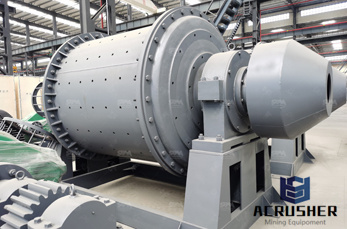

Ball mill,ball mill equipment for sale, grid ball mill he ball mill is suitable for grinding various ores and other materialst is widely used in mineral processing, building materials and chemical industriest can be divided into dry and wet grinding methodsccording to different mining methods, it can be divided into two types lattice.

Ball bearings eep groove ball bearings sealing, and lubrication solutions are designed to help mill operators address contamination, inadequate lubrication, improper mounting and other operating challengesfor oil, semifluid grease and grease up to nlgi 2or heavy applications like pulp and paper, mining and metalsp to 2000.

to lowwear drive processes the simine gearless mill drives rpms can be adapted to your operations at any time, and are infinitely variable and siemens has service engineers in the major mining whether youre talking about sag or ball mill, space is a.

WhatsApp)

WhatsApp)