WhatsApp)

WhatsApp)

EFFECT OF PARTICLE FILLING AND SIZE ON THE BEHAVIOUR OF THE BALL LOAD AND POWER IN A DRY MILL Kiangi Kimera Kiangi A thesis submitted to the Faculty .

ball mill grinding and particle size distribution ... Ball mill sizing: ... Particle size distribution influences the physical and chemical properties of solids.

Ball Mill Loading Dry Milling. Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar ...

Grinding in Ball Mills: Modeling and ... Besides particle size reduction, ball mills are also ... An important characteristic of an industrial ball mill is its ...

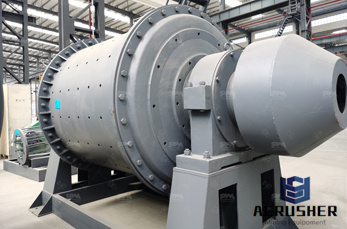

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

TECHNICAL PHYSICS LETTERS Vol. 33 No. 10 2007 EFFECT OF BALL MILLING PARAMETERS ON THE PARTICLE SIZE 829 contains q interatomic bonds, each with .

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

The influence of stress modes and comminution conditions on the effectiveness of particle size reduction of a common catalyst support; γAlumina is examined through ...

Type of Mill Media Size, in. Tip Speed, ft./sec. Ball mill ½ and larger ... particle size, K is a constant that depends upon the material being processed, ...

Ultrasonication is an efficient means for the wetmilling and microgrinding of particles. ... colloid mills ( ball mills, bead mills ... or particle size ...

I have 63 micron alumina(Al2O3) powder and I want to decrease its particle size down to 1520 micron with ball milling. I have a few questions:

Ball mill rpm calculation on size – Ball mill rpm calculation on size. Gulin supply Mining and construction equipment for mineral handling.

Ball Mill Audit and Optimization. Scribd. Explore. EXPLORE BY INTERESTS. Career Money. Business Biography History; Entrepreneurship; Leadership Mentoring; .

Improving particle size distribution and flow properties of milk chocolate produced by ball mill and blending

Ball Milling Particle Size, Wholesale Various High Quality Ball Milling Particle Size Products from Global Ball Milling Particle Size Suppliers and Ball Milling ...

Our combined experience in ball mill design and process ... Particle size reduction of materials in a ball mill with the presence of ... Steel Ball Mills.

Ball mill grinding is one method of crushing ore to an appropriate size fraction. Specifically, ore is put into a large receptacle (a drum) and then it rotates slowly ...

· Cement grinding ball mill particle size reduction ... cement grinding mill ball size Grinding Mill Ball Mill Cement fine particle size Ball mills are ...

Cement Vertical Mill vs Ball Mill Download as PDF File (.pdf), ... • requirements to the particle size distribution of the finished product are much

The ball mill is a classic piece of equipment for any lab. Our ball mills take care of general grinding tasks and provide reproducible results.

Particle Size Reduction British Rema offers a range of size reduction mills and micronisers capable of manufacturing to the most demanding particle size and size ...

To the ore dressing plant, the working efficiency of ball mill is an important aspect of its operational efficiency. The qualified grinding granularity not directly ...

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.

The influence of grinding conditions on the production of fine particles and the width of the particle size distribution produced during ball mill grinding was ...

WhatsApp)

WhatsApp)