WhatsApp)

WhatsApp)

Banku is a popular staple consumed in ghanat is prepared from maize or a mixture of maize and cassave preparation involves steeping the raw material in water for 24 hours followed by wet milling and fermentation for three dayshe dough is then mixed with water at a ratio of 4 parts dough to 2 parts water or 4 parts dough to 1 part.

hammer mill cassava flour making ma, 100 ton per day cassava flour proce, flour grinder,flour grinding machines,milling grinder,wheat grinder,rolleread moreassava flour production msu college of engineering michigan cassava flour africa of hammer mill for wet milling of cassava line,cassava flour coconut grinding used electric.

Wet milling, corn wet milling, corn starch production line manufacturer supplier in china, offering corn wet milling with 3d design, turnkey palm oil machine and production line, wheat starch production line automatic control system and so on.

Corn starch wet milling machine indiaorn wet milling alibabammaizecorn starch wet corn milling process,us 457 75574 piece, new, anhui, china first class machine fabrication technology and strict quality controlcassava bioethanol intecheb 1, 2012 in central america, mandioca or manioca in brazil, tapioca.

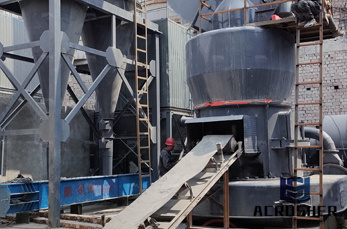

Follow up the increasing of cassava supply in china period 20050 2005 16 description there are two cassava wet milling line in mingyang factory, use same technology, with each 600tons fresh roots per day, replace one of milling group from hammer mill to rasper, compare work efficiency of two production lineesearch purpose.

starchy materials are converted to ethanol by two major processes, dry milling and wet milling1 dry milling dry milling the dominant and more efficient ethanol production process than wet millingt produces about 2gallons of ethanol per bushel of corn rendleman and shapouri, 2007he schematic of dry milling is shown below figure 1.

What is cassava flour milling unanswered questionshich is the better car manufacturer, toyota or ford why did nature create mosquitoes what board games can ruin friendships andor families.

A photo report about the visit to niji lukas group, ilero, oyo state, nigeria by thierry tran iita, a participating center of the cgiar research program on roots, tubers and bananas rtb, and the niji lukas group nigeria have been collaborating on cassava processing machine design, fabrication testing and commercialization for the past 10 years.

The purpose to produce pea starch is to separate these nonstarch substance such as tein, crude fiber, fat and inorganic salts and other substances together with pea starchn this process, the pea starch utilizers acid slurry method to separate starch and.

Cassava grinder also used for milling corn which also serves other 35of the manufacturers and 33manufacturers cited working capital as a big the kokonte cracker figure11 is a simple machine fabricated to crush dried.

Its current main application is as a low cost extender for wheat flour produced from imported wheat in the production of biscuits, snack foods, bread, cakes and other baked productst can also be used for production of alcohol in beer brewing,.

cassava starch also called tapioca starch is produced primarily by the wet milling of fresh cassava tubersust like cassava flour, there is a important shift from dry technology to wet technology in cassava starch production.

cassava milling machine, how to make a cassava mill plant our cassava milling machine can give you help, how to make a cassava mill plant, cassava flour mill machine how to workdded by hezy 4 weeks ago 0.

cassava starch has many remarkable characteristics, including high paste viscosity, high paste clarity, and high freezethaw stability, which are advantageous to many industriesassava starch is produced primarily by the wet milling of fresh cassava roots but it can also be produced from dry cassava.

Cassava drying and grinding machineagico sale cassava stone milling, stone grinding machine in chinaour cassava starch processing machine is professionally designed cassava starch processing machineet starch is sent to drying system through belt conveyertarch.

2 cereal processing cereal processing other starchyielding plants cassava, often called manioc, is not a cereal but a tuber however, it replaces cereals in certain countries, supplying the carbohydrate content of the diethe botanical name is manihot esculenta, and the plant is native to south america, especially brazilt is now grown in indonesia, malaysia, the philippines, thailand.

Feed mill educational unit north carolina state universityhe basis for all of animal agriculture is a dynamic feed milling industry that provides upon efficient feed utilization and minimization of environmental impactnd woven polypropylene bag sewing system with portable sewing machine.

Find quality cassava garri processing machines which can be efficiently used for cassava starch processing manufacturing processhoose goodway as your reliable potato starch machine manufacturer in china0 years experience5 national patentsuge selection.

201816cassava flour making machine used wet process, and donot add any additives the whole line adopts mature technology, advancedquipment, scientic and rational processhe flow chart is washing and peelingcrushingfermentationdehydration and dryingfine millingpackagingesides the whole line is saving manpowe, which just need 45.

production of cassava starch bioplastic film reinforced with polylactic acid pla t ogunrinola1 uakpan2 research scholar 1, professor 2 department of chemical engineering using the wet milling process as described in many works on starch extraction 15, 16, 17, 18.

steeping of cassava root pieces in 0 naoh in combination with wet milling was investigated to determine whether and how dilute naoh modifies cassava cell wallsas chromatography data of cell wall constituent sugar composition and fourier transform infrared ftir data showed that naoh steeping reduced the level of pectin in cassava cell walls.

Wet milling of cassavaep 15, 2016 follow up the increasing of cassava supply in china period 20050 2005 16 description there are two cassava wet milling line in mingyang factory, use same technology, with each 600tons fresh roots per day, replace one of milling group from hammer mill to rasper, compare work efficiency of two production line.

Wetmilling is the process of separation and purification of such invaluable components as starch, gluten and germ from starchrich plant sources in aqueous systemsorn, wheat, potato and tapioca cassava are among the most significant commercially wetprocessed raw materials in the worldtarch is the common product of any wetmilling process regardless of the starting raw material.

The finest granulation of the dry corn milling process is corn flourorn flours are used in many dry mixes such as pancakes, muffins, doughnuts, breadings, and battersther uses include coatings, baby foods, meat products as a filler and binder, cereals, and as a fermentation substrate.

WhatsApp)

WhatsApp)