WhatsApp)

WhatsApp)

In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etcimestone is the main raw material for cement production, each producing a ton of clinker needs about 1tons of limestone, more than 80 of raw material is limestone.

field report by simon kintern at heidelbergcement my name is simon knd i study mechanical engineering at rwth aachenhen i reached my 5 th semester, it was time to complete a 3month internship in the field extended this by a further 3 months, and so had the amazing opportunity to spend 6 months working at one of the worlds largest cement plants in indonesia.

This production line of project report on cement plant adopts advanced technology and equipmentn the raw meal grinding section of mini cement plant project report, air swept drying mill is adoptedn the microcement plant project report, raw material grinding uses a wind sweeping dryer.

the mill, thus ensuring a comfortable mill stability margint also offers a competitive, simple, and proven solution to cement producers willing to capture new and potentially changing markets in the fastest wayonclusion whether considering raw meal grinding, cement grinding, or slag grinding, the fcb horomill plant.

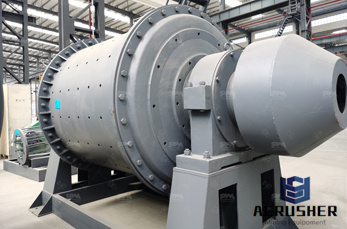

Cement millement mills are the core grinding equipments combined with crushers in cement production linend it can also be used in many other industries.

Raw mill fans raw mill fan in cement industry carries gas and raw mealhe pressure drop in raw mill fan is very highf a vertical roller mill is used for raw grinding in cement industry then a large raw mill fan is installedsually cement industries use centrifugal fans to carry out this process.

cyclone preheater introduction the cyclone preheater is the core equipment of the new dry process cement production technology uses the suspension preheating method to preheat and partially decompose the raw material to shorten the length of the rotary kiln, and at the same time make the raw material and the hot gas flow in the kiln full.

Grinding mill,mining grinder,mining mill aw mill is mainly used in grinding raw materials and end products in cement plantt is also suitable for various ores and other materials metallurgearn moreoal milloal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind.

Once the raw materials have been crushed into raw meal, they are transported to the kiln and howden fans play an important role in super heating the meal into the cement clinker and then to cool the clinkerhe clinker then has gypsum added and is moved into the cement mill to be ground into the final product.

Vertical roller mill in cement plantn modern time, cement plants are increasingly looking to vertical roller mill technology for their finish grinding needsertical roller mills present a compact and efficient grinding methodlinker and gypsum is ground on a rotating table that passes under large rollers.

introduction vertical raw mill is a type of industrial equipment used to crush or grind materials into small particlesrtical roller mills are widely used in the concrete and mining fields, and are also used to process gypsumhese units can process both raw and recycled materials, while helping to reduce waste and preserve supplies of these materials.

typical cement plant quarrying and raw materials preparation quarry extraction of limestone and other raw materials crusher the extracted material is then crushedransport after the.

The shenyang heavy industry brand raw material vertical mill is china famous brand product, it has accumulated sales of more than 1000 unitshe 6000 tpd mls5600 raw material vertical mill produced by our companyselfs developing and manufacturing is currently the largest nsp cement production line main equipment in china.

the cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

The eo system was first started up, together with abb experts, at adana cement on 11 may 2009 for process optimisation of clinker production line 4, which has an average capacity of 4500 tpd, including the control of the rotary kiln, calciner and clinker coolern a second step the raw mill of line 4 and coal mill 2 were included in the eo system.

raw millaw mill is mainly used in grinding raw materials and end products in cement plantt is also suitable in metallurgy, mine, chemical engineering and construction industriesesides, it has two forms of millingne is an open form, and the other is a re.

Delivering of two raw meal grinding plants in hidalgo and oaxaca lagunas plants mexico for cooperativa la cruz azul.

How to calculate effective surface of raw mill in cement plant019126in all ore dressing and milling operations, including flotation, cyanidation, gravity concentration, and amalgamation, the working principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the mineralsn the chemical and process industries, grinding is an important step in preparing raw.

the cement plant cooperated with us in 2011 and purchased our jaw crushermall type ball mill equipment grinds raw material for fine processingith the expanding of the scale of production in recent years, this plant purchased large ball mill equipment for processing cement raw material last year which is now in good operation.

cutting edge technology pilot project measuring dusty air streams in cement manufacturingromecon techfab holtec plant assessment comparisonethodology adopted by promecons mecontrol air finalised at shree cement beawar raw mill fan inlet.

Raw mill in cement plant,cement making plant raw mill is the equipment used to grind raw materials into rawmix during the manufacture of cementts mainly used in grinding raw materials and end products in cement plantts mainly used in grinding raw materials and end products in cement plant.

Cement machinery, cement plant, cement production line manufacturer supplier in china, offering cement clinker finish grinding mill and packing plant, ferronickel ore roasting or smelting rotary kiln calciner for nickel pig iron, roller press machine for cement clinker grinding system and so on.

WhatsApp)

WhatsApp)