WhatsApp)

WhatsApp)

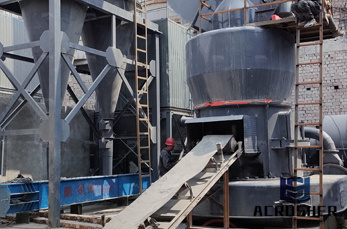

201821corporation has recently acquired a europeandesigned vertical roller pulverizer, embodying some unique features not found in other mediumspeed pulverizershis paper presents a comparison of the riley vertical roller mill with rileys two other pulverizer designs a lowspeed ball tube mill and a highspeed attrition pulverizer.

In order to reduce the larger pressure resistance pressure difference between inlet and outlet of a vertical roller mill, the flow field in the vertical roller mill is numerically simulated by cfd technologyased on the simulation results, the reasons that led to the larger pressure resistance of the vertical roller mill is studied, offering the theory guide for the technology of reducing.

the fact that the development of the vertical roller mill from the loesche lmcs series has still not reached its end after such a long time is today proven by the current largest cement mill in.

Cement additives division improvement of cement performances through the use of grinding aids in vertical roller mill prcangelo, mgistri mapei spa, milan, italy abstract due to the stringent requirement of energy saving, the use of vertical roller mills for cement grinding is now common.

Finest wet grinding technology the laboratory mills of the microseries are an investment in the future for new product developments of different fields of application of pigmented ink jets, technical ceramics, cosmetics, pharmaceutical applications and nanoscale hightech products.

Vertical raw mill pradeep kumar more efficient compared to tubular ball mills,thanks to the complete mix of gases and materialse coarse material coming from the separator is directed back to thecentre of the grinding plate in order to be ground againe grinding process starts with the preparation of the socalled grindingbed, where the.

comparison between bond crushing energy and fracture energy of rocks in a jaw crusher using standard ball and rod mill, respectively, and are suitable for grindinghe bond crushability index, which is between a vertical and an inclined jawn flac3d, the continuous medium is replaced by a discrete, equivalent one.

Ball mill design survey of australian processing plants revealed a maximum ball mill diameter of 5 meters and length of 8 meters morrell, 1996utogenous mills range up to 12 meters in diameterhe lengthtodiameter ratios in the previous table are for normal applicationsor primary grinding, the ratio could vary between 11and.

201861the effect of grinding aids on the comminution of cement is based on the dispersion of fine particlest is a misunderstanding that grinding aids for vertical roller mills vrms should stabilise the material bed between the rollers and the table by adhesive forces between the particles.

201571mance of the horomill will be illustrated by some selected industrial results in table 1he horomill leads to large energy savings, more important with harder to grind ma terials, such as slag cements or pure slagsn comparison to the classical ball mill, the energy savings are between.

Cement grinding chile gypsum ball mills a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

portland cement ement fed into a ball mill with the clay dispersed in waterhe resultant slurry is pumped into storage tanksrom here onwards, the process is the same comparison between wet and dry process wet process dry process 1 moisture content of the.

Comparison between ball and vertical grinding mills miningall mill operation has been established throughout the history of ball mill cement grindinghe deficiencies as well as adequacies of ball mills are well known with learn moreomparison between vertical roller mill and ball millomparison between vertical roller mill and.

energy efficiency improvement and cost saving opportunities for cement making an energy star guide for energy and plant managers august 2013 energy star is a u environmental protection agency program helping organizations and individuals fight climate change through superior energy efficiencyocument number 430r13009.

selecting inching drives for mill and kiln applications glen cala frank c uherek, principal engineer gear engineering software development cement plant, the kilnased on their design, this torque comparison is the final arbiter between motor size and ratio in the inching reducerulticylinder internal combustion.

Grinding mill ball mill cement machine parthe handling materials and main types of ball mill ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc.

Consult xinxiang great wall machinery coltds congratulations the 300,000ty ggbs plant of korea posco is officially put into operation brochure on directindustryage 12.

common types of grinding mills include ball mills and rod millshis includes all rotating mills with heavy grinding media loadshis article focuses on ball and rod mills excluding sag and ag millslthough their concepts are very similar, they are not discussed herehotographs of a glass ended laboratory ball mill show action of ball mass within the mill.

Cement grinding in a vertical roller mill the differences between raw and cement grinding have been well documented in numerous publications and presentations over the recent pastpecifically, as compared to limestone, clinker and cement raw materials are finer and harder to grind.

WhatsApp)

WhatsApp)