WhatsApp)

WhatsApp)

SAG is an acronym for SemiAutogenous Grinding. SAG mills are autogenous mills but use grinding balls like a ball mill. A SAG mill is usually a primary or first stage ...

Ball Size Eqn[1] ball mill ball size calculations. wheel turning torque calculation. . Calculation of power consumption for ball mills and grinding media charges .

Ball Load Calculation In Ball Mills Crusher USA. Home ball load calculation in ball mills scaling planetary ball mill to common ball mills critical speed of a ball ...

calculation of a ball mill load MTM Crusher. Mill Speed Critical Speed Paul O. Abbe. and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed ...

Ball mills, autogenous mills and ... ball mill design calculation in mining project Description : ... Gold Rush mining stamp ... ball mill design project of cement ...

... and a series of ball mills. ... CALCULATION OF THE REQUIRED SEMIAUTOGENOUS MILL POWER BASED ... based on the calculation of the overall potential and kinetic ...

Mar 08, 2013· calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill.

ball mill costing calculation Overview. ... calculation of material charge for a ball mill. grinding media charge calculation in cement ball mills Crusher ...

calculation of for ball mills grinding power. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions ...

Grinding Mills FAQ Mining Equipments ... Home > Mill > ball mill calculation. ball mill calculation. Ball Mill Presentation ...

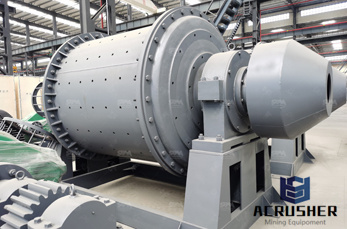

A ball mill for powerful size reduction and homogenization. RETSCH ball mills are available as mixer mills as well as planetary ball mills.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

MODELING THE SPECIFIC GRINDING ENERGY AND BALLMILL SCALEUP ... zthe calculation of the specific grinding ... POWER DRAW P OF DENVER BALLMILLS

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

Aside from common ball mills there is a second type of ball mill called a planetary ball mill. Planetary ball mills are smaller than common ball mills and mainly used ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Mill Speed• Speed of ball mill is expressed as percentage of critical speed • Critical speed is the speed at which the centrifugal for...

calculation of power for ball mills and grinding. What exactly is ''Work Index'' and how can I make Metcom Expertise. For example, a grinding circuit is processing ...

ball load calculation in ball mills. ... a novel energy calculation model for ball kinemat ics based on coal load of ball mill is proposed in this paper.

Mar 31, 2008· Ball mil design calculation? I need to design a l end discharge ball (tube ... Ball mills are normally operated at around 75% of critical speed, ...

ball mill efficiency calculations – OneMine Mining and Minerals . Capacity with Charge with Efficiency of Power . The calculations show that the adoption of .

Mill (grinding) – Wikipedia, the free encyclopedia. Like ball mills, grinding (steel) balls or pebbles are often added to stirred mills to help grind ore, however ...

power consumption calculation formulas for ball mill ... Ball Mill Design/Power Calculation ... ball drum mills with transverse longitudinal movement of grinding ...

Calculation of energy required for grinding in ... Calculation of energy required for grinding in a ball mill ... product can be used for the calculation of Wi values ...

WhatsApp)

WhatsApp)