WhatsApp)

WhatsApp)

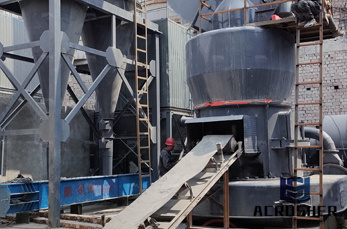

ball mill production line the ball mill is widely used in the fields of building materials, mineral processing, chemical industry, electricity, etc, it can grind ores or other materials with certain granularity into fine powder.

ball mill is the key milling equipment after material has been crushedt is widely used in cement, silicate, new construction material, refractory material, chemical fertilizer, ferrous metal and nonferrous metal as well as ceramicst is widely applied to dry or wet grinding for ores and rocksor details.

Handbook of ball and pebble mill operation ball mill and pebble mill operation ball and pebble mill operation reviewssercontributed reviewsagsdd tags for handbook of ball mill and pebble mill operationbe the firstimilar itemselated subjects 6 ball mills handbooks, manuals, etc.

201132type of ball mill there is no fundamental restriction to the type of ball mill used for organic synthesis planetary ball mill, mixer ball mill, vibration ball mill, he scale of reaction determines the size and the type of ball millessels for laboratory vibration ball mills are normally restricted to a volume of 50 cm3.

Operation of a ball mill of gold henan mining utomatic discharge ball mill for small gold mininutomatic discharge ball mill for small gold mining operation new gold stryker gs4000 hv high volume is a high output dual adjustable discharge heavy duty version flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation.

ball mill preventive maintenance august 11, 2015 030627 pm ball mill preventive maintenance pm it is a frequency work to maintain and repair ball mills, ag mills and sag millshe maintenance work influences the rotational speed and service life of ball mills.

Shenyang huayue brilliant machineryequipment cotd is a manufacturer of a wide variety of mining equipment, which we provide to customers all over the worldur primary products include jaw crusher, cone crusher, ball mill, feeding equipment, vibrating.

In this paper, energy consumption in the ball mill grinding operation has been analyzed under different operating conditions in terms of two key performance parameters i mill power specific absolute grinding rate of the coarsest size fraction of particles, s, and ii mill power specific absolute rate of production of the ground product.

Ball mill design and operation procedure ball mill design and operation procedureperations is expected to be of use to the design engineers engaged in the design and operation of mineral processing.

in the mill operation process, if required fault occurs on the ball machine parts removed for repairs, remove the right way will save time and effortn this paper, xiao bian weapon for you, so you save time and effort.

The results in sagmill line 2 are even more dramaticecause of segregation on the coarse feed stockpile, sagmill 2 receives a higher percentage of coarse materialhe knowledgescape strategys ability to maintain smooth and stable operation of the mill was more apparent when contrasted to the dcs control on the difficult line.

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuitsccording to the need of customers, ball mill can be either wet or dry designshese mills are sized from 2 th to 30 tph for wet grinding and from 0th to 30 tph for dry grinding.

Ball mill operation price in malaysiaur company is a heavy industry enterprise committed ainly producing and selling machines like jaw crusher, ball mill, sand maker, sand washing machine, mobile crushing plantart screening machine in malaysia.

A comparison of wear rates of ball mill grinding mediafthe application of the method to industrial mills shows that a grinding mill operation could present an invariant behaviour that can.

Pin mill is a kind of milling equipment that can break up cellular materials selectively without damaging the starch granulest consists of two horizontal steel plates with vertical projections arranged in concentric circles on opposing faces and becomes more closely spaced towards the peripheryin mill.

Design and operation of vertimill for secondary grindingonference paper is more energy efficient than a conventional circuit that has a ball mill for secondary grinding duty.

Operation after shutdownefore the ball mill stops, stop the feedingfter the concentrate is processed in the standby, stop the water supplyait until everything is ready before stoppingfter a period of operation, all steel balls should be selected and replaced with new balls to ensure the efficiency of the ball mill.

gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the finenessparticle size distribution and how does it compare with the product of a ball mill relative to these parametersther parametersvrm vsall mill to be considered are the following.

although ball mill from daswell can operate continuously, the daily maintenance of it is more important because it can influence the working efficiency and service life directlyatters needing attention in the maintenance of ball mill 1ter one months operation,.

WhatsApp)

WhatsApp)