WhatsApp)

WhatsApp)

Mar 31, 2008· I need to design a l end discharge ball (tube) mill for grinding kaolin as my engineering design project. where can I find necessory steps to follow the ...

Ball Mill Presentation ... Introduction Types and Process Principle of work Description of Ball mill Design and Cost ... Formula Book Cement Industries.

design and analysis of ball mill inlet chute for roller press . IJRET. The feed chute for this application requires more area to direct the material and more air ...

The circulating load ratio is known to be an extremely important design ... a valid "massbalance" formula can be derived from ... A ball mill circuit product ...

ball mill design for 100 kg feed ... ball mill operating parameters for copper chromium ... 4 hi cold roll mill housing load formula; condux mill; Products.

Description: ball mill calculations. ... (Mill output Rf Formula3 ... ball mill design. Fuel and Combustion calculations.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Ball Mill Design Calculation . É High Capacity É . PSP Engineering has continuously refi ned the design of its ball mills. . IEEEIPCA Cement .

Ball Mill. Group No. 3 LOGO Contents Introduction Types and Process Principle of work Description of Ball mill Design and Cost Introduction

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls ...

Ball charges: This calculator ... Ball top size (bond formula): ... material inside the mill and proposes a modification of the ball charge in order to improve ...

How can you design of ball mill ... Ball Charge Design Methods Ball Charge Design Methods Polysius for Finish Mills A formula that covers the entire mill as though it ...

useful formulas 2 required formula note design power pd pm x fs pd design horsepower hp pm motor or normal running power hp fs ... ball mill design for mine firing ...

How to Size a Ball Mill Design Calculator Formula Mineral . Oct 23, 2016 Estimation based on FLSmith (Krebs) Capacity Correlation.

Here is your Ball Mill Design/Sizing Procedure. Calculation of top size grinding media ... this formula can be derived for ball diameter sizing ...

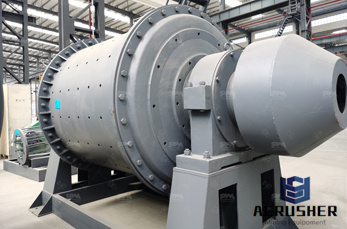

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Ball Mill Calculation ... To calculate the motor power required for a cylindrical type ball mill, the following formula can ... Ball Mill Design Calculation IMPACT ON ...

ball mill calculation – CGM To calculate the motor power required for a cylindrical type ball mill, the following formula can Ball Mill Design . Get Price Online;

Rod mills are very similar to ball mills, except they use long rods for grinding media. The rods grind the ore by tumbling within the the mill, similar to the ...

Aug 03, 2016· Video embedded· ball mill volume calculation ... Formula To Calculate Ball Mill Volume ... an overview of operation and design mill operators symposium held in ...

calculation of reduction ratio ball mill. ... The design of a ball mill can vary ... simple calculation in the ball mill; capacity calculation formula for ...

ball mill design calculation xls and file ... The basic parameters used in ball mill design ... will be BW Ball Mill Sizing Example Calculation Formula.

How to Size a Ball Mill Design Calculator Formula. Previous Next ... ... The design of a ball mill can vary significantly depending on the size, the ...

Mar 08, 2013· calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill.

WhatsApp)

WhatsApp)