WhatsApp)

WhatsApp)

MultiCoal Fired Boiler Optimum Control uses a proprietary algorithm from MHPS. It monitors the characteristics of coal and the status of combustion in the boiler ...

Steam Boiler For Rice Mill, ... 2017 factory prices industrial coal fired steam boiler for rice mill sugar factory pharmaceutical textile industry. Ad.

Pulverizing coal in boiler is an important factor ... The fineness of the coal is also important in overall mill efficiency and in ... Coal Pulverising in Boilers.

coal mill Download as PDF ... This blocking of the raw coal inlet will with time result in a stopped coal flow from the coal mill to the boiler, and since the ...

Wood Fired Boilers. Hurst Boiler specializes in the design, ... Agricultural Backup, Gas/Oil, Bark, Chipped Mill Waste, Coal, Construction Debris, Hulls, Hog Fuel ...

power plant coal mills YouTube 18 Sep 2012 ... In coal fired power plant, coal mill is used to grind, pulverize and dry coal before the coal is transmitted the boiler

1 EPRI study on large coal fired utility boilers (greater than 600MW) using pulverizers with capacities ... BallRace Mills comprise the majority of coal

Pulverized coal fired boilers ... Running a Coal Fired Boiler at the Best Efficiency. ... There are a few minor losses in boiler which can also be tuned are the mill ...

Boiler Control for FossilFired Utility Boilers ... Boiler Control for FossilFired Utility Boilers 2 ... regulation of the unit''s coal mills.

Combustion measurement and optimization 4. ... or high mill pressure erosion of mill, ... CFD Modeling of 500 MW Tangential Coal Fired Boiler Page 49

Hurst Boiler produces hybrid or ... agricultural backup, oil, bark, chipped mill waste, coal, construction debris, hulls ... Hybrid HD Boilers can burn ...

A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust ...

Pulverized coalfired boiler Wikipedia. A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by The raw coal is then fed ...

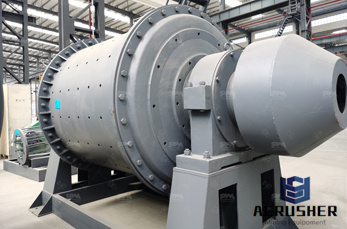

The working reliability of ball mill directly affects the reliability of coal pulverizing system and even boiler unit. The correlative degree analysis and balanced ...

Coal Properties and its influence on ... • Ash analysis is used to characterize the slagging and fouling potential of coal in the boiler. ... Influence on Coal Mill

For paper mills and cogeneration, everything old is new ... Flambeau burns coal, ... 2 thoughts on " For paper mills and cogeneration, everything old is new again ...

Discover the Coal Gun, featuring unparalleled convenience and efficiency in a Coal Stoker Boiler. The Coal Gun is manufactured for Residential, Commercial ...

Neha Engineering Works Offering Power Plant, Boiler, Mill Coal in Vadodara, Gujarat. Read about company and get contact details and address.

Coal Feed Systems For Boiler and Coal Milling Plant. EMERGENCY DISCHARGE TO PULVERISER FROM COAL BUNKER QThe arrangement and geometry of the bunker/feeder/mill has ...

Mill Boiler, Wholesale Various High Quality Mill Boiler Products from Global Mill Boiler Suppliers and Mill Boiler Factory,Importer,Exporter at

paper making machinery Industrial Coal Steam Boiler Price For Paper Machine Mill ... paper making machinery Industrial Coal Steam Boiler Price For Paper ...

COAL MILL COAL MILL Derek Stuart, AMETEK Land, and Todd Collins PE, Hoosier Energy, US, ... pulverised coal to the boiler, a total of 195 tph per boiler.

Other wastes include coal mill rejects/pyrites, cooling tower sludge ... In a pulverized coalfueled boiler, coal is dried and ground in grinding mills to ...

Coal mill is employed to grind, pulverize and dry coal before the coal is transmitted the boiler. Service online. ; ;

WhatsApp)

WhatsApp)