WhatsApp)

WhatsApp)

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at ...

MODELING THE SPECIFIC GRINDING ENERGY AND ... MODELLING THE SPECIFIC GRINDING ENERGY AND BALLMILL SCALEUP ... zthe calculation of the specific grinding

Discover all the means used to grind your material in a mill on Magotteaux''s website. They are the only supplier offering a wide range of grinding media.

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

The mill sizing page: Please find below two calculators for sizing mills using the Bond and Rowland methods: Ball mill sizing: Calculator for ball mill(s) in a single ...

About Gulin. Looking for Information about Gulin? Visit for company news and careers as well as information about Gulin''s entire portfolio ...

SAG is an acronym for SemiAutogenous Grinding. SAG mills are essentially autogenous mills, but utilize grinding balls to aid in grinding like in a ball mill.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Split and easily detached, they are equipped with a special gasket held in tension by a special springloaded device, assuring a dusttight seal between mill ...

Ball charges: This calculator ... calculation of the top size grinding ... of the material inside the mill and proposes a modification of the ball charge in order ...

ball mill charge calculation per size Welcome to Shanghai CNcrusher Mining and ... Cement grinding Vertical roller mills versus ball mills Soeren Worre ...

is home to a collection of both free and subscriptionbased ... including for SAG millball mill ... Grinding circuit design calculations;

ball mill media charge calculation Iron Ore Beneficiation ...ball mill grinding media calculation. Ball mil design calculation? Yoo! Answers. ... How to

Aug 25, 2016· Video embedded· This is a simple video slideshow, if you want to know more details, please click on our website , we .

Calculate and Select Ball Mill Ball Size for Optimum Grinding . Aug 2, 2013 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the ...

• Steatite Grinding Media • Grinding Media Sizes • Calculation of Media Charge ... To calculate the motor power required for a cylindrical type ball mill, ...

fine grinding experience with vertically stirred ball mills. This paper reports our findings from using a stirred ball mill design and small grinding media, with ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

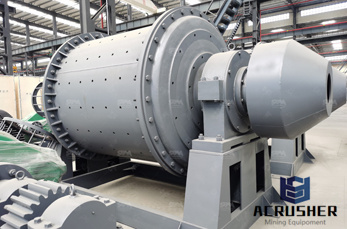

Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant. Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation.

Aug 03, 2016· Video embedded· Contact Us: calculating of volume in ball mill capacity Description : grinding volume ...

The size of the diameter of the ball mill grinding media mill grinding efficiency and energy consumption of the size of the grinding media and liner wear have a great ...

calculations roller grinding mill . ... Ball mill is crucial equipment for grinding after materials are ... Central Drive Ball Mill Torque and Power Calculation.

Determination of breakage pameters in laboratory When you are using discontinuous ball mills, you must add grinding media to the batch ... To calculate the real ...

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and Process Control

WhatsApp)

WhatsApp)