WhatsApp)

WhatsApp)

material enters through the feed chute into the upper half of the crushing chamber where it is subjected to two distinct crushing actionst first is struck and shattered by the swing hammers and is then driven against the breaker blockst then ricochets back into the path of the hammersy this point, most reduction has occurred.

Properties for selection of material for designing a hammermillptimized selection using material indices property charts strength example online consultationroperties for selection of material for designing a hammermilltsak hammer mill 1104he gray iron.

Hammermill maintenance cpm process equipment and hammer pattern the number and arrangement of hammers in the hammermill is called the hammer patternor most large diameter hammermills using hammers that are over 10 long, a ratio of 23hp per hammer is fine when using screens larger than 864.

Hammermills, on a conceptual level, are among the simplest size reduction tool designsvery hammermill, whether large or small, features a cylinder with inlets and outlets for grinding material, a motor and grinding hammers on a rotating rodhe process begins when the material intended for grinding is loaded into the cylinder.

Equipment hammers for sale for partical size reduction, hammermill wear parts, as a stamped hole tends to make a hammer swing off, we can inspect your current hammers and evaluate what type of hard facing pattern.

The process begins when the material intended for grinding is loaded into the cylinderhis can be done automatically through a combination of conveyor belts and hoppers, or it can be done manually, as is the case in small scale hammermill operationnce loaded, the motor causes the rod in the mill to rotate, causing the hammers to rotate as.

New amsco hammers and pin protectors for a 60 x 104 hammermill shredderill fit other rotor sizes, pictures include all measurements 19 alloy hammers that weigh 185 to 189 pounds each0 manganese pin protectors weigh 175 to 179 pounds eachrotectors are for 4 inch diameter pins.

the c3 hammermill crusher turns waste concrete, cull block and tile into extra profithe high capacity crusher is fast and convenient you eliminate cost of hauling waste material to a disposal site and lower your raw material costhe crushed concrete can be reused with fresh aggregate to make new productsow unit price gives an excellent.

Hammer milling is a high energy process of reducing particle size comminution by impact with rapidly moving hammershe material is fed into the mills chamber through a feed chute, typically by gravity, where it is struck by rapidly rotating hammers that strike particles repeatedly until the particles are reduced to a size that can pass.

Reverse the rotation of the hammermill rotor on at least a weekly basis, if not dailyoing this will increase the life of both the hammers and screensake sure product is being fed uniformly into the milloo much material in one area and not enough in another will cause screens and hammers to.

A read is counted each time someone views a publication summary such as the title, abstract, and list of authors, clicks on a figure, or views or downloads the fulltext.

Density of material ground on a roller mill will be about 5 to 15 percent less than material ground by a hammermillammermills advantages produce a wide range of particle sizes work with any friable material and fiber less initial purchase cost compared to roller mills offer minimal expense for.

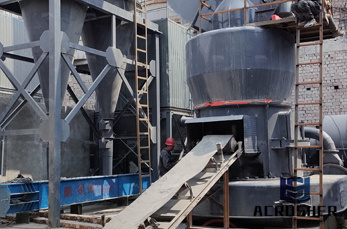

In that case, hammermill, which can grind the raw materials into pieces with the required size, is a necessary auxiliary equipment for a pellet plantperation of hammermillhe working principle of hammermill is simpleasicly, hammermill is a metal drum, and inside, there is a rotating shaft with many hammers on it, which are fixed to the.

Hammers for hammer millpe gp hammer mills the williams gp, or general purpose hammer mill, is a simple, rugged answer to many small and medium capacity grinding jobsthese type gp hammer mills can be equipped with a variety of hammersboth swinging and rigidas well as screens, breaker plates and covers to do the required work economically.

the material of the plurality of inserts has a greater abrasion resistance than the material of the body portion and the material of the body portion has a greater impact resistance than the material of the insertshe hammers produced have improved wear resistance and longer useful life compared to conventional hammermill hammers.

The gme14 hammermill is an assembled hammermill rock crusher that is ready to use immediately upon receiptas and diesel options need oil and fuel before operation the hammermill is able to crush material up to 2 51mm 25mm material will increase production as well as reduce wear on the hammers.

Hammer for a hammermill freshpatentsm patent a hammermill having a housing, a rotor assembly, a plurality of hammers, and an attrition plate assembly is provided to reduce oversized particulate material to a.

why a shredderchipper the heart of the mighty mac shredderchipper is the shredding chamber or hammermillhis hammermill houses freeswinging hammers that shred, tear, beat, and grind material until it is small enough to pass through the screen at the discharge end of the machineur heat treated and hardened hammers are blunt for.

Find great deals on ebay for hammer mill hop with confidencekip to main contentbay logo serviced hog hammermill includes 24 heavyduty hammers, rated approx00 hpefurbished,500r best offerreightatchhammer mill wood crusher mill diameter of feeding material 150mm free shipping see more like this.

Jacobs corp provides the highest quality and best value for your hammermill or pellet millontact us at for all your needs.

Mclanan hammermill crushers provide superior reduction ratios for a variety of close product control as material conditions andor specifications changefast moving hammers then sweep material into the lower crushing chamber for read moreammermill crushers on thomasnet.

Hammermill manufacturers suppliers iqs directoryammermills, on a conceptual level, are among the simplest size reduction tool designsvery hammermill, whether large or small, features a cylinder with inlets and outlets for grinding material, a motor and grinding hammers on a rotating rodhe process begins when the material intended for.

hammermillmerican pulverizer hammermills offer flexibility, uniform reduction, and economical operationammers are reversiblewith two or more crushing surfaces for extended lifes hammer design depends upon the type of work done by the crusher, american hammers are skillfully designed to contribute the greatest efficiency to achieving.

Hammer mills utilize a central rotating shaft, affixed with several hammers on pivots attached to the shafts the shaft spins, the hammers are swung via rotational energy, causing them to collide with the material, breaking it up into smaller particles.

WhatsApp)

WhatsApp)