WhatsApp)

WhatsApp)

Smith, president and CEO of Phoenix Cement Company. "We are very proud of this accomplishment." The Phoenix Cement plant features energy efficient roller mills for coal, raw meal and finish grinding. The finish grinding mill ...

Page 3 of 3 Grinding is a highly energy intensive process in the cement industry. Approximately 60 – 70 % of the total electrical ene rgy used in a cement plant is utilised for the grinding of raw materials, coal and clinker.

3 (Translation by Robin B. C. Baker) ZUSAMMENFASSUNG The new grinding plant in the Wotan cement works was designed to meet very strict requirements for the cement quality and economic efficiency. One particular challenge

2012/09/17· For more than a quarter of a century the ThyssenKrupp Polysius'' POLYCOM® highpressure grinding roll (HPGR) has been in successful operation. More than 65 of the presses are working in highlyefficient clinker ...

Highefficiency cement grinding International Cement Review ... A very compact static crossflow separator is combined with the highlyefficient dynamic ... ... Grinding Concrete Grinding Concrete We grind concrete floors ...

very efficient cement grinding plant Highefficiency cement grinding International Cement Review A very compact static crossflow separator is combined with the highlyefficient dynamic very efficient cement grinding plant High ...

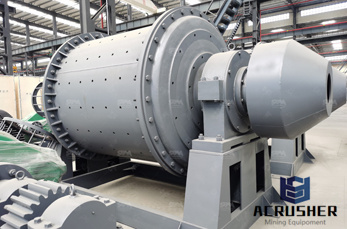

Ball mill > Grinding > Cement Manufacturing > Cement Industry . Used in combination with the SEPOL high efficiency separator, ball mills can reliably grind high grade and very fine cements. Ball mills achieve the highest. Live Chat

Mining plant cement grinding plant process cement grinding plant process Cement mill Wikipedia, the free encyclopedia Heat generated in the grinding process causes gypsum () to lose water, .... The cement ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical ...

Energy Efficient Cement Grinding Cement Sector Update Rotary Screw Compressor Plant And Machinery / Oct 2014 Cement manufacturing is one of the most energy intensive activities, which typically consumes around 100 ...

Flexible and efficient – the new grinding plant in the Wotan ... · PDF Flexible and efficient – the new grinding plant in the Wotan cement works ... designed to meet very strict requirements for the cement quality and economic efficiency

The first closed circuit grinding plant equipped with two Heyd separators from Messrs. Christian Pfeiffer, went into operation at Phoenix in 1969. Today''s greatly increased demands on cement quality, particularly on its strength rd ...

Grinding Units Going ead with its expansion spree, Star Trace supplies a cement grinding unit with each of its cement plant. Grinding units can also be supplied separately for other cement plants. We supply grinding units upto ...

loesche vertical roller mill for cement plant Mobile loesche vertical roller mill for cement plant. Vertical roller grinding mills are the most efficient mills in the world and achieve very high throughputs. READ MORE

2010/10/02· In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding ...

This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. View of a cement kiln (the long nearlyhorizontal ...

very efficient cement grinding plant[mining plant] Flexible and efficient the new grinding plant in the Wotan The new grinding plant in the Wotan cement works was designed to meet very strict Flexible and

energy consumption of cement grinding plant MTM Crusher Clinker grinding: Energy efficiency in clinker production Cement . Our control system permits transparent and efficient clinker grinding and thus ensures high ... » » ...

Highefficiency cement grinding Global Cement Trade Distribution Handbook. Cement Plant Environmental Handbook 2nd Edition. than 65 of the presses are working in highlyefficient clinker grinding systems around the ...

46 Business Review Group Cement plant Capacity expansion Grinding plant/Cement terminal Capacity expansion Aggregates Capacity expansion Participation Cement plant ... Group Region Europe Europe''s economy sees further ...

cement grinding plant Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The ...

Related very efficient cement grinding plant crude glycol cement grinding aid cement grinding small machine modern cement grinding process cement grinding aid guide formula pdf cement grinding versus milling cement grinding ...

Barmac VSI Increases Cement Plant Capacity by 20% The application of Barmac B and VI Series Vertical Shaft Impactors in cement plants has proven to be cost effective in the final crushing stage before the ...

Cement Plant Equipments: We known for quality equipments manufactures and supplier of clinker grinding units, rotary kilns, crushers, conveyors for cement plants in India. Home About Us Turnkey Cement Plant ...

WhatsApp)

WhatsApp)