WhatsApp)

WhatsApp)

ball mill design and efficiency improvement factors factors that affect in extraction efficiency of mills ... Search factors affect efficiency of ball mill to ... grinding mills efficiency factors jordan grinding mills efficiency factors jordan 171 ...

2007/07/18· all types of rotary mills (including ball mills and SAG mills) in one algorithm or formula. But they do not presently do so without some serious compromises. If you are comfortable with one of those formulas, and it works 11 ...

めまれている· Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very ...

SagTension Calculations: Refinements and Enhancements Made by Trimble Energy Solutions by: Jacques Hamian and Yair Berenstein Abstract Sagtension programs have traditionally calculated the conductor''s sagtension ...

2017/08/21· This paper presents an overview of current practical approaches to semiautogenous grinding (SAG) mill liner designs as they affect longterm liner performance, mill performance, and the interaction between grinding media ...

SAG is an acronym for SemiAutogenous Grinding. SAG mills are essentially autogenous mills, but utilize grinding balls to aid in grinding like in a ball mill. A SAG mill is generally used as a primary or first stage grinding solution.

Incorporation into a cost function of both a utilization factor and . with the volume of cane crushed and the seasonal plant capacity in some time. their influence o. Get Price Minetomill optimisation: effect of feed size on mill It is ...

2011/06/10· Trends with selection and sizing of large grinding mills — filed under: Print Edition by The Australian Journal of Mining — created Jun 10, 2011 01:06 PM By Damian Connelly, director/ principal consulting engineer ...

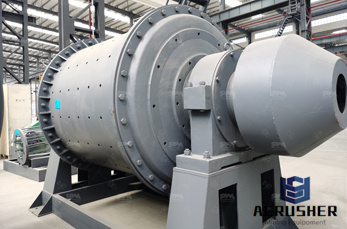

Factors Affecting the Efficiency of Ball Mill College Essays ... Ball mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new building ...

Steadystate is especially important in AG/SAG mills where a harder component can build up over time and negatively affect operations. Another advantage of this test is the generation of a seasoned charge. This has particular ...

Presently SAG mills are mainly driven with variable speed drives, ... The power factor of the motor is low and changes depending on the load. A power factor ... 12 poles, beside the lower capital cost compared to the traditional...

It includes ball mills, in which the material to be ground is enclosed in a What Affect the Grinding Efficiency of Ball Mill College Essay Jun 20, 2014 What Affect the Grinding Efficiency of Ball Mill Factors Affecting The Efficiency ...

Specifically, at the equipment terminals, these factors affect the voltage sag type: 1. Fault type Voltage sags are primarily caused by system faults. Each fault type has a different effect to the voltages at the fault point, which Ø Ø ...

2017/08/07· Today''s high capacity semiautogenous grinding (SAG) mills expend vast amounts of energy and in doing so consume tons of shell liners and steel balls, while processing ore. The energy efficiency of these high ...

2014/08/25· May I slightly rephrase the question, Barry? Can people say that either they are happy that they selected sag mills or say they made wrong selection? In either case, if examples and a bit of information on ore type/top ...

The ''froth factor'' is a measure of the air contained in the froth. It is quantified by filling a measuring cylinder or bucket, of known volume, with froth and measuring the froth column. After air dissipation the remaining water and solids ...

For more than 30 years, Polydeck has designed and manufactured trommels of all sizes for use in SAG, ball and rod mill applications. Our trommels offer high performance, incorporating PipeTop II stringers and the Maxi screen panel ...

fines correction factor sag milling – Grinding Mill China fines correction factor sag milling. ... SAG Mills 10 – Rod Mills 10 ... two factors that affect the grinding efficiency of ball mill. » Learn More Is intrinsic factor really affected by ...

Effects of ore characteristics on product shape properties and breakage mechanisms in industrial SAG mills . Author links open the author workspace. Parviz Pourghramani Opens the author workspace Opens the author A × ...

There are three principal methodologies for sizing SAG mills that are .... factor of that accounts for the difference in grinding efficiency of a... Get Price SemiAutogenous Grinding Mill Specific Energies Using a CEEC 16 Oct ...

THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 89 Pilot plant description The milling pilot plant consists of two containers mounted on top of each other (see Figures 1 and 2). The bottom ...

Optimized Iron Ore Blast Designs for SAG/AG Mills Jack Eloranta Eloranta Associates Inc Abstract Few "minetomill" issues inspire as heated debates as blasting for SAG AG mills. Increased blast energy may produce ...

influence of feed size on ag/ sag mill plant data which illustrates the influence of feed size distribution variation on mill performance and discusses the reasons why ag and sag mills respond the way ... Broadly the approach entails ...

There are slightly different versions of the Factor B for different styles of mills. The equation presented below is for wet overflow ball mills. The Outokumpu reference gives the base mill charge density for these formulae as 310 lb/ft ...

WhatsApp)

WhatsApp)