WhatsApp)

WhatsApp)

Steel Rod Mill Uses Flexible Programming For Grinding Of Carbide ... Two grinding operations are typically performed on these carbide rolls. The first is a topping operation (an OD operation) using a straightfaced 14inch diamond...

DEVF~LOPMENT, APPLICATION AND OPERATING RESULTS OF THE CENTER PERIPHERAL DISCHARGE ROD MILL BY DAVID PORTER HALE, JR. A THESIS submit ted to the faculty of the SCHOOL OF MINES AND ...

This forum began as Clark''s Classic Bamboo Rod Forum, founded by Clark Davis for all who share a passion for classic rods. The forum is now owned by Whitefish ... ...but not quite ready to run finished strips. We moved it ...

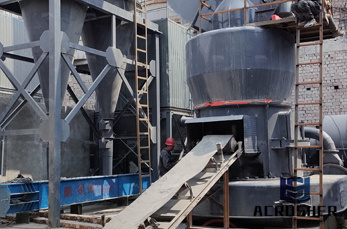

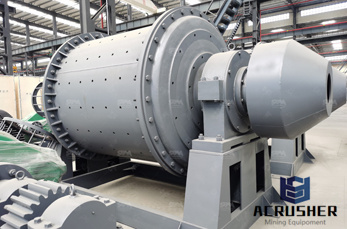

Ball Mills vs Rod Mills Ball mills and rod mills are both excellent mining machines for grinding ores into fine powders and particles. However there are some advantages to using rod mills rather than ball mills for larger mining projects ...

2015/05/31· Problem: Shell erosion in the mill''s outer shell produced a leakage. When this was detected concern was raised by RCA and Maintenance team that the

Rod Dimensions Rod tangling is a problem that should be avoided by using straight rods. Rods < 6 meters are generally never straight. Rods should be 152mm shorter than mill length. Rod life is maximized of rod lengthtomill ...

» hot rolling mill problem solving wire rod The Hot Rolling Process California Steel Industries The Hot Rolling Process ... The Hot Mill rolls slabs weighing up to 30 tons between 30" and 74". Steel slab 8 to 9 inches thick and up ...

bamboo strip preparation Choosing a Culm I will give you some general information about preparation of bamboo strips and some pointers needed to mill bamboo strips on my Hand Mill. It is not my intention to provide complete ...

Choosing Connecting Rods | R;R Racing Products /howtochoosetherightconnectingrod Aluminum, Steel, or Titanium Rods? How to choose the right connecting rod There are two major categories for ...

MINIMIZATION OF SURFACE DEFECTS ON BARS AND WIRE ROD ORIGINATED IN BILLET CASTING(1) Cristian Genzano (2) Luis Pablo. Reda (2) Jorge Madias (3) ABSTRACT In order to minimise surface defects in long ...

The following cost advantages should be considered when evaluating rod mill grinding: Rod Mills use low cost grinding media. Less power is required since grinding rods are not cascaded and operate at lower peripheral speeds. Higher ...

problem in rods in rod mill Ball Mill; Raymond Mill; Vertical Mill; High Pressure Mill; MXB Coarse Powder Mill; MTM Medium Speed Mill; MTW European Trapezium Mill; ... Tom Morgan Rodsmiths The ...

Hot rod Wikipedia, the free encyclopedia Hot rods are typically old, classic American cars with large engines modified for linear speed. The origin of the term "hot rod" is unclear. Roadsters were the cars ...

Rod mill and ball mill Rod mill is usually wet overflow type and can be used as the first level open grinding. Ball mill is widely used in industrial production. Rod mill is called rod mill because the grinding medium in the barrel is steel ...

Section Head – Rolling Mills Allen York, Minimum 14 years experience in production of a high a speed wire rod mill of which, personalised problem solving . ... View Charles Hyatt''s professional profile on LinkedIn, I started as the ...

comminution kinetics Columbia University particles between the rods causes the material with the least grindability ... and lizenithne in a laboratory rod mill ... Commentary on the apparatus of the Bond rod mill work index The ...

2008/05/14· I want to machine some 4340 billet steel connecting rods for my pulling tractor using my Hurco kmb1 cnc mill. I will probably use 2" thick plate for material. My problem is that these rods are 1 3/4" thick and about 13 ...

Radioactive waste Wikipedia, the free encyclopedia Those isotopes emit different types and levels of radiation, which last for .... The back end of the nuclear fuel cycle, mostly spent fuel rods, contains fission ..... Mill tailings are ...

Today I will share how to select steel grinding rods for you. 1. High wear. Round steel owing to low hardness, toughness was poor, resulting in consumption is very large, and indirectly led to the magnetic part of the task is heavy ...

steel Billets, bars, and rods | metallurgy |.Rod mills are similar Problem In Rods In Rod Mill to bar mills at the front end, but the finishing end is different. Rods have a smaller section ( to 15 millimetres in diameter) and are ...

As the heavy rod charge transmits a considerable force to each rod, a rod mill can not be built too big. A shell length above 6100 mm can not be recommended. As the length to diameter ratio of the mill should be in the range of 1,21 ...

2014/12/13· : 110 Copper Round Rod, Unpolished (Mill) Finish, H04 Temper, Standard Tolerance, Inch, ASTM B187: Industrial Scientific Interesting Finds Updated Daily Amazon Try Prime Industrial Scientific Go EN Sign in ...

Jan. 25, 1966 MCLEAN ETAL 3,231,432 PROCESS FOR THE QUENGHING OF HOT ROLLED RODS IN DIRECT SEQUENCE WITH ROD MILL Filed Oct. 8, 1964 2 SheetsSheet l FIG. I 1N VENTOR. DAVID W. MCLEAN ...

Process improvements on rod mills DMengineer surface defects on hotrolled Hot Rolling Mill Problem Solving Wire Rod wire rod and bar coils. By Brian Wire Association International''s 68th Annual Conven tion, Cleveland, Ohio In ...

WhatsApp)

WhatsApp)