WhatsApp)

WhatsApp)

From the above formula we can be calculate the critical speed of the ball mill. . ... the correct power required to grind ore in a SAG mill, ...

Basic Concepts for Beginners. ... Material removal rate is how fast in cubic units your mill is making chips ... If you reduce your spindle speed too much ...

The Complete Guide to CNC Mill Feeds and Speeds. ... How do you calculate your feeds and speeds? ... Choose the best stepover for speed and surface finish.

Calculate and Select Ball Mill Ball Size for Optimum Grinding. In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and ...

How to calculate the ball mill speed CME. . (calculate) the correct or optimum ball size that allows for the ... formula to calculate critical speed in ball mill ...

Oct 21, 2016· Video embedded· Ball mill ball size calculation ... (calculate) the correct or optimum ball size that allows for the best and ... Ball Mill Critical Speed .

Calculate Ball Mill ... ensuring the appropriate mill speed ratio, ball size and ... (calculate) the correct or optimum ball size that allows for the best and ...

Calculate the Speeds and ... and Plastic Cutting Carbide End Mills with these General Machining Guidelines ... RPM Revolutions per Minute (Speed) IPT ...

Mill Speed Critical Speed . (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved . >>Chat Online

Aug 03, 2016· Video embedded· ball mill volume calculation ... (calculate) the correct or optimum ball size ... Ball Mill Critical Speed Working Principle .

Ball Mill Operating Speed ... calculate horse power of a ball mill, ... is the wrong value to use when calculating the correct rpm value to achieve a ...

Calculate and Select Ball Mill Ball Size for Optimum Grinding. In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and ...

End Mill Training Speed and Feed Calculations. ... (MPM) The cutting speed of the end mill. This system is used in all countries that use the Metric system.

Ball Nose milling application information. Feed, speed and diameter compensation. Recommended ball nose cutting speeds. Troubleshooting.

Grinding Mill Calculation In. Ball ... The "Critical Speed" for a grinding mill is defined as the ... (calculate) the correct or optimum ball size that allows for ...

Calculate Ball Mill ... ensuring the appropriate mill speed ratio, ball size and ... (calculate) the correct or optimum ball size that allows for the best and ...

Closed Circuit Grinding ..... critical speed to achieve the correct tumbling patterns. Even though tumbling mills ... calculate critical speed of ball mill.

Calculate and Select Ball Mill Ball Size for Optimum Grinding . Aug 2, 2013 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the ...

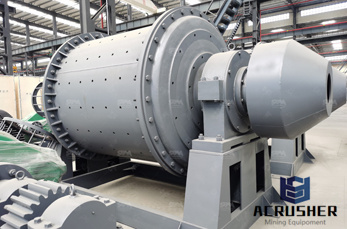

Ball Mills Mine This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their ...

Critical Speed Of Ball Mill Calculation India; ... (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be ...

Jan 15, 2017· How to Calculate RPM. Revolutions ... Knowing how fast an object turns is important in determining wind speed, ... Although the correct .

Our free speed and feed calculator can be used to determine the spindle speed (RPM) ... such as an end mill or face mill.

Calculate correct ball mill speed Gulin Machinery. Home»Products»Calculate correct ball mill speed. Calculate correct ball mill speed. ... The Ball Mill Finish ...

THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 89 ... These data are then used to calculate the total pulp and ball

WhatsApp)

WhatsApp)