WhatsApp)

WhatsApp)

Full Vent System Clinker Collector Gypsum Separator Collector To Product Storage Mill Collector OSepa Separator Primar Air Secondary Air Finish Mill Mill

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

Inside a (stationary!) cement mill. The partground clinker and steel grinding media are clearly visible. (Picture courtesy Castle Cement).

GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING. Changing impact conditions can cause conventional grinding media to either work harden or .

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

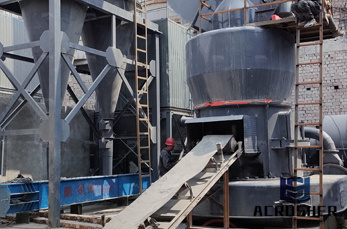

The JOYAL Threering Micro Powder Mill(ultrafine mill) is for superfine grinding materials with hardness less than 6 in Moh''s scale and humidity less than 6 ...

About Gulin. Looking for Information about Gulin? Visit for company news and careers as well as information about Gulin''s entire portfolio ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

RSG Inc, located in Sylacauga, Alabama specializes in fine powder technology. The company manufactures air classifiers, ball mills and stirred media mills for ...

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane, Australia email:

A wide selection of ROLLER MILLS available. Call us for more details.

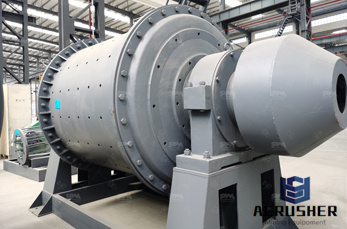

The ball mill is a key equipment to grind the crushed materials, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

Cost economic grinding media balls for mines and minerals processing industries from AIA Engineering Ltd.

PDF: English RadiusEnd Cylinder and Banded Satellite Sphere Ceramic Grinding and Milling Media Based Upon Magnesia Stabilized Zirconium Oxide. Engineered for ...

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

Union Process offers a full line of high quality grinding media balls, engineered to meet your most demanding milling applications.

Capacity Enhancement and Energy Conservation in Cement Plant Batra*, Chhangani**, Dinesh Satija*** and R. B. Garg**** Holtec Consulting Private Limited, .

How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder.

FOX Zirconium Silicate Grinding Media is the right ceramic grinding media for you. Why take chances with any other inferior milling media for your bead milling.

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Milwaukee® Magnetic Tape Measures are Nothing But Heavy Duty®. Using Nylon Blade Protection and a 5Point Reinforced Frame, they offer up to 10X Longer Blade Life ...

The World Least Wear Rate High Chrome Cast Grinding Ball Supplier The PREFERRED global grinding media supplier for LAFARGE, HOLCIM, Italcementi, .

WhatsApp)

WhatsApp)