WhatsApp)

WhatsApp)

2 HPGR High pressure grinding roll for the minerals industry Introduction During its relatively short history in minerals processing, HPGR technology

Guaranteed cement quality. We know the importance of product stability to our is why we control quality at every stage of production

process ball grinding mills ZCRUSHER. process ball grinding mills. and as the second stage in two stage grinding circuits. cost of cement mill; grinding ball mill .

Specializing in precision power transmission components including couplings, helical drive systems, gearboxes and screw jack actuators

Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of ...

In the two stage crushing system. This grinding is done ... Inside the ball the ... is ground in a cement mills used for coal grinding .

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns.

Find instructions on how to make a knife from a professional knifemaker, Wayne Goddard, here. Get the complete tutorial from BLADE magazine.

Pictures of the Taig Lathe, Mill Other Tools and Accessories . Here are pictures of the Taig Micro Lathe and Taig Milling Machine, pictures of my machines and other ...

The name Ticonderoga, or as the Algonquin and Iroquois Indians called it – Chinandroga, loosely means "the place between two lakes."

Cement Ball Mill for Grinding Mica Sales ... Cement Ball Mill for Grinding Mica. Cement ball mill is an oldest ... and as the second stage in two stage grinding ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

The duallobed design is optimal for clinker grinding because it supplies two ... ball mill cement grinding. ... Operational Experience from the United States ...

Picture of kilns 13 in 1914, viewed from the west, from an early Newells advertisement. The stack to the rear is that of the finish mill power plant.

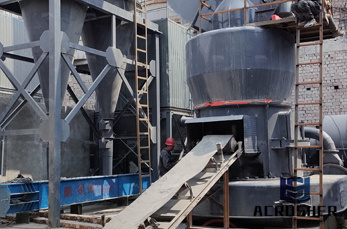

Feb 10, 2016· VRM vs Ball Mill for Cement Grinding. ... Overall ball miil is good option for Cement mill but only has limitations for higher capacity, as two ball mill .

Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals ...

Sep 17, 2013· Video embedded· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and .

Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, rubberlined mill, with SiemensAllis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch.

Figure 2: The integrated cement plants and standalone cement grinding plants in the UAE in 2014, colourcoded by installed integrated cement production capacity in ...

CEMENT MILLS Twochamber ball mills for the cement industry are available in different designs. ... Design of cement grinding mill with hydrodynamic pad bearings.

CGM Ball Mill Pulverizing Application. Ball mills are primarily used for single stage fine Grinding, reGrinding, and as the second stage in two stage Grinding ...

Cut a cube of rock and then trim off all the corners with your saw. Use a coarse grinding wheel to smooth it more towards a sphere. Put your lumpy ball on the plug ...

3 Coal Mill : 25 t/h, Vertical roller mill, 355 kW Cement Mill : 120 t/h Ball mill, 2,800 kW + Roller Press, 500 kW Diagnosis The plant operation was ...

Grinding in Ball Mills: Modeling and Process Control ... Grinding in ball mills is an important technological process applied to ... metallurgy, cement production, ...

WhatsApp)

WhatsApp)