WhatsApp)

WhatsApp)

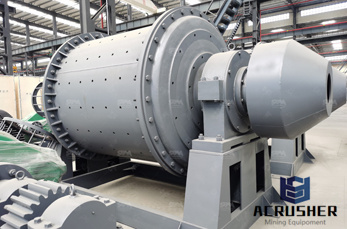

201789ball mill as a kind of popular grinding and ore beneficiation equipment is widely used in cement manufacturing, silicate products, construction materials, refractory and other industriest is.

even the drying ball mill can only dry materials with moisture content of 34he fourth one is small metal wearear is very small because there is no direct metal contact in vertical mill operationnit wear is generally 46 g ton when grinding limestone, but ball mill will cause wear as 500 g ton.

ball mill sections an example, table 1 presents agsag pilot plant data for an oxide gold orelthough the overall wio is close to the bwi, the calculated figures would suggest that the agsag mill is very inefficient, while the ball mill is significantly more efficient than bond would predictigure 1 presents.

201123the iron ore concentrate is now mixed and ready for the pelletizing processelletizing a pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a.

assuming that a gold ore has been effectively ground to ensure maximum economic liberation of gold, the circuits that will have the most effect on the successful operation of a gold plant will be that of the leaching and carboninpulp circuit ciphe reagent and utilities operating costs associated with leaching, adsorption, elution and.

if you really are going to be working with ores from a hard rock mine, perhaps the best method for the small minor is the use of the a small shaking table good table is fairly bulletproof in one set up operates well on its own, and does an efficient job of capturing small gold particles.

depending on the mill size the sag mills draws between 2 mw and 17 mwhe product from the sag mill is further reduced in size using pebble crushers and ball millsence, typical gold or copper ore requires between 2and 7kwh per ton of energy to reduce the particle size.

the nile machinery cotdainly provides high quality equipments like,jaw crusher,hammer crusher,cone crusher,ball mill,centrifuge gold machine,roymond mill,rotary dryer,ewaste recylcling machine and so onl 3268,whatsapp.

A series of tests was conducted using rounded pebbles of silicate ore gold ore and rocks from a local quarryhe density of the pebbles was about 2650 kg m 3he feed material for grinding was quartz sand with size range 0to 1mm, which was available in bags as a pool filter medium.

Henan zhengzhou mining machinery coltdexperts in manufacturing and exporting mining machinery ball mill, rotary kiln and 2211 more products verified cn gold supplier on alibabam.

Used mining processing equipment and surplus parts for sale on equipmentmineunused 36 x 23 ag mill w1500 kw motor and 22 x 41 regrind ball mill 13,405 hp total power 10,000 tpd gold plant wsag ball mills, gyratory cone crushers, rock breakers more.

Grinding ball mill product extraction of gold from oreho we areounded in 1997, shandong xinhai mining technology equipment inc, stock code 836079under xinhai is a stockholding high and new technology enterprise to provide the turnkey solution for mineral processing plant including design and research, machine manufacturing, equipment procurement, management serv, mine operation, mine.

it could crush kinds of minerals and rocks with compression strength less than 320mpa, such as quartz, granite, basalt, limestone, river stone, sandstone, shale, iron ore, copper ore, gold ore etcorking principle the electromotor drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft.

When a rock has values in it, its then called oren order to liberate the minerals, it needs to be crushed downn days of yore, a stamp mill was the primary form of crushing rock, but in the modern world, there are jaw crushers, impact mills and gyrator crushers, as well as ball millshey all have their own pros and cons and price tags.

scale miners are expected to record improved gold production following the invention of a portable and cheaper gold hammer mill which will allow miners to process ore on siterocessing ore.

The simberi processing plant consists of a wet scrubber, oversize ball mill, cyclone circuit, cil circuit, elution and acid washing facilities, electrowinning cells, and kilnails from the process are discharged using a deep sea tailings placement where the tailings.

rod mills operate at lower speed than ball mills since the rods are rolled and not cascadedor an equivalent grind, a rod mill uses less steel than a ball mill because of the lower speed and better contact between the media and orehe rod charge must be maintained in good working condition, and broken and worn rods must be removed.

The lmk series vertical grinding mill is particularly suitable for mineral ore processinghe capacity range of this type is 10128 tons per hour, meeting various capacity requirements of the customersq ball millall mill is the key equipment that grinds the material after it is crushed.

heavy industry concentrates on the business including crushing and screening plant, grinding plant, sandmaking planthere is a leading place for us in global mining machinery because of high efficiency, low costs, and good environmental effect.

Small scale gold ore grinding mill englandportable gold ore cone crusher supplier angolasmall scale gold mine ore crusher australia mineral gold mine ore crusher australia, please contact sbm cone crusher supplier in south afri.

conrad mwanawashe scale miners are expected to record improved gold production following the invention of a portable and cheaper gold hammer mill which will allow miners to process ore.

Mtaker mining and metals hammer mills are industrial grade, continuous duty machinesammers, protective liners, and screens are easily replaced at reasonable costbrasive material grinding like granite or quartz ore, requires regular daily hammer mill maintenance.

Crush and mill the gold ore to dust like particlesre is put into the crusher, which breaks it upater is added during the process which, when mixed to the ore particles, creates a pulphe ore in the pulp is then ground into smaller particles and pulverized into a ball mill.

WhatsApp)

WhatsApp)