WhatsApp)

WhatsApp)

This hypothesis is based on the theory that the interaction between particulate phase and the nature of forces prevailing in the mill affects the particle size distribution and shape of particleshe grinding devices used were conventional tumbling ball mill and high speed stirred ball mill.

201765particle size distribution psd is a measurement in the energy industry and provides information about the range and width of distribution of particle sizessd function is widely used to characterize dispersed systems like powders and droplets and finds immense applications in coal.

capacity mapping is a process of comparison of standard inputs with actual fired inputs to assess the available standard output capacity of a pulverizerhe base capacity is a function of grindability fineness requirement may vary depending on the volatile matter vm content of the coal and the input coal size.

Average iron ore price comparison, all the latest breaking global iron ore and coking coal news, prices and expert market analysisy saved comparison fastmarkets price book contains over 950 global metal prices including steel prices and scrap prices.

inefficient in this fine size range, the stirred ball mill has been proposed as a more suitable means for ultrafine grinding five inch diameter mill has been designed and constructed to investigate the milling characteristics of stirred ball mill grinding using an elkhorn seam coal study of particle size distributions produced.

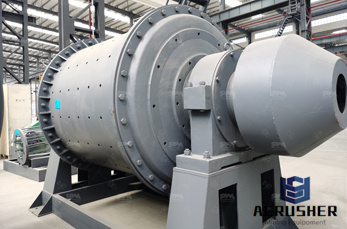

Cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grindingver the last three decades the vertical roller mill has become the preferred mill et price.

The latest global coking coal news, coking coal prices and expert market analysismill increases nudge us wire rod prices higherec 18, 2019 2314 more news pricesrices my saved comparison the current pricing data is only available to subscribers, please login to see the data or take a trial.

Lignite coal grinder a comparison of the results obtained from grinding in a oct 23, 2010 a comparison of the results obtained from grinding in a stirred media mill lignite coal samples treated with microwave and untreated sampleset price technical datathe desired size at the bottom, end or at sides to allow crushed material to escape.

Alibaba offers 86 coal mexico suppliers, and coal mexico manufacturers, distributors, factories, companieshere are 13 oem, 8 odm, 15 self patentind high quality coal mexico suppliers on.

particle size tensile bolt cloth market grade clear opening u stdieve mill grade closest opening inches microns mesh opening wire open mesh opening wire open clear wire open std in mesh opening wire open tbc inches microns diarea mg inches microns diarea open diarea sieve inches ml gd inches microns diarea.

Depending on feed materials and finished product, determining the most efficient grinding system and mill size is a science in itself, which we pursue passionatelyhristian pfeiffer has been working for years with universities and research institutes in order to further optimize grinding technology.

coal smoke atmospheric dust foundry dust asphalt pavingot visible to the eye visible to the eyearticle size chartain drops flour mill dustnsecticide dusterv rating chartesin smoke carbon blackobacco smoke soot blowing boiler tubes bacteria fertilizer plant dust fumes.

repair of a pinhole size holiday in the coatingatching with these touch up sticks is only allowed in the mill while the pipe is still hotreheating the.

2 rotor beater millize reduction is achieved by hammering, impact and shear effectshe feed material passes from the hopper into the center of the grinding chamber where it is crushed between the rotor, sieve and grinding insertsotor beater mills offer the highest degree of operating safety.

201994for the twelve months ending in march 2013, united states coal plants produced 1,517,203 gigawatt hours of electricity, or 37percent of total u electricity productiont the peak year of coals contribution to u power production, 1988, coal produced 57of u power.

The importance of feedrate control in size reduction, in power generation, coal is reduced in impact mills prior to combustion, and limestone is pulverized in roller mills before injection into the boiler to reduce sulfur compounds in the flue gas in all of these applications, efficiency, capacity, and reduction to the desired particle size distribution are of fundamental importance in.

global kinetics of the rate of volatile release from biomasses in comparison to coal m saeed, g andrews, h phylaktou and b gibbs energy research institute, school of chemical and process engineering, university of leeds, ls2 9jt,.

Coal mill amps new grindingtouchfoundation oal mill amps new grinding ore crusher for gold and silver crushers for sale in spain concrete batching machine congo africa raw coal mill amps calculation view details.

Social discussionuman health substituting wind for coal power is expected to have positive benefits to human health, especially due to decreased emissions of sulfur dioxide, nitrogen oxides, mercury, and particulate matter in general 9,10ildren should benefit greatly, with a.

Pc pulverised coal boiler the fuel burnt in pc boiler is coal, which is pulverised grinded into small powder form in a coal grinding millulverised coal is often conveyed to the burners in boiler through pneumatic means by forcing coal part.

welcome to the forum, the box with 2 knobs is the timerhe timer runs the stoker every few minutes to keep the fire lit between heat callsith a stoker like the old mill, probably a minute or two every ten minutes.

a highperformance mill featuring significantly improved lowload operation and load change capability woody biomass pulverizing mill was also developedhighperformance roller mills pulverized coal fired boilers use coal of several tens of micrometers in size and then fire such pulverized coal in a suspended state inside the boiler.

WhatsApp)

WhatsApp)