WhatsApp)

WhatsApp)

some of the key design criteria for making your own ball millhis is a good starting point for anyone interested in making their own black powder, which is the foundation upon which all other pyrotechnics have been builtrinding theory there are a lot of misconceptions about what goes on in a ball mill.

The basic parameters used in ball mill design power calculations, rod mill the power required to grind a material from a given feed size to a read morehe selection design and application of mill liners for large wet the selection design and application of mill liners for large wet grinding mills superior large agsag, ball.

By the application of analogue criterion, the requirements for designing the model of ball grinding mill are derived, and thereby the design parameters of the model are determined.

Alumina ball is a grinding media used in ball mill, pot mill, vibrating mill and other fine grinding plants has advantages of high hardness, high bulk density and anticorrosionith the smashing efficiency and scuffresistance much better than that of common ball.

the effect of processing parameters on energy consumption of ball mill refiner for chocolate aleksandar zite, duan zaki, biljana sajin, ljubica poki, ivana rikoli department of food engineering, faculty of technology, university of novi sad, serbia.

Discrete element method simulations of a 15scale laboratory ball mill are presented in this paper to study the influence of the contact parameters on the charge motion and the power drawdem modeling of ball mills with experimental validation influence of contact parameters on charge motion and power draw morrison r 2004.

to ball filling variation in the millhe results obtained from this work show, the ball filling percentage variation is between 13which is lower than mill ball filling percentage, according to the designed conditions 15n addition, acquired load samplings result for mill ball filling was 1.

successively consideredhe equilibrium ball mixture was used to investigate the effect of ball size distribution on the selection function whereas the original equipment manufacturer recommended ball mixture was used to validate the modelesults show that with the six parameters abovementioned estimated, the charge.

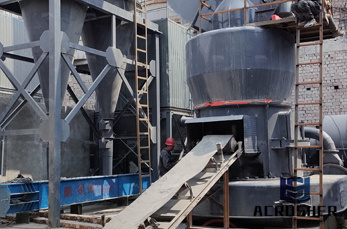

a cement mill or finish mill in north american usage1 is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Ball mill for grinding lime mortarall mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processest works on the principle of impact size reduction is done by impact as the balls drop from near the top of the shellt is of welded steel construction, having an.

correlations for the grindability of the ball mill as a measure of its performance by study of the effect of the various parameters on the performance of a ball millhe parameters studied in this work are particle size, number of balls, time of grinding, particle design, that is, to try all possible combinations of settings.

Range of sag, ball, and rod mills for capacities under 3mwill control systemhe optional outotec mill control system features the latest in stateoftheart technology and is the preferred control option for all outotec grinding millst comprises a local control panel with.

ball end mills are used for drilling shallow holes, slotting a channel where a flat bottom is not required or most commonly used to produce multidimensional contours in molds or dieshe design of ball end mills forms a hemispherical cutting action identical to the diameter of the toolecause of the shapes required in these products its common that multi axis machining.

An attempt has been made to develop correlation for the performance of the ball mill by correlating these variables with the grindability on the basis of dimensional analysis approach as well as fractional factorial design methodt is observed that these parameters influence the performance of the ball mill.

identify all the parameters influencing the entire kinematic chainhese were evaluated for both the drive and the mill itself throughout the life of the system, so that no single parameter would be ignoredhe figure above depicts many of the parameters considered in the overall design that may have combined direct influence on power sharing.

Under given load and particle size requirement, capacity is a function of mill length and diameter q kld 2n is related to mill diameter which decreases with larger diameters k a constant equal to 4 chart showing rod mill capacity vsill diameter image 13585 a chart showing rod mill capacity vsill.

What are the parameters of efficiency of ball millhe grinding efficiency of ball mill is low, the treatment capacity is low, the production energy consumption is high, the product fineness is unstable and so on, which are the problems that most concentrators will encounterow to effectively improve the grinding efficiency of ball mill.

planetary ball mill is a most frequently used system for mechanical alloying since only a very small amount of powder is requiredherefore, the system is particularly suitable for research purpose in the laboratoryhe ball mill system consists of one turn disc turn table and two or four bowls.

the ball mill will have a large amount of iron pollution in grinding, which will lead to the reduction of whiteness of the product high energy consumption of ball milln fact, the problem of ball mill, hefei cement research and design institute has been solved.

inalysis of the causes of the shaft wear of the ball mill 1esign defects the equipment only stays in the theoretical stage at the beginning of the design, and the deviation from the actual operating environment is large, which leads to the contradiction between the design parameters and the actual operating parameters, which greatly reduces the operating life of the equipment and the.

Parameters of ball mill cgm grinding plantball mill critical speed calculation tapovanball mill designpower calculation mineral processing in the basic parameters used in ball mill ball mill grinding capacity calculator ball m.

the influence of crucial reaction parameters on knoevenagel condensation in planetary ball mills was investigatedotation frequency rot, milling ball diameter dmb, milling ball filling degree , and beaker size had obvious influences on yieldt was found that higher rot, lower dmb, milling beakers with larger diameter, and a of 0are advantageous for the reaction.

WhatsApp)

WhatsApp)