WhatsApp)

WhatsApp)

2017/03/27· Planetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of planetary ball mills has extended to mechanochemical ...

size Definition of size reduction: It is the process that reduces large solid unit masses Importance of size Reduction in Pharmacy: (Advantages) ? Mechanical Engineering Ball mill. Fluid energy mill. Oscillating ...

2017/07/15· : Process Engineering of Size Reduction: Ball Milling () by Linda Gong Austin and a great selection of similar New, Used and Collectible Books available now at great prices.

Sud Sushant et al. Int. Res. J. Pharm. 2013, 4 (8) Page 58 Methodology Mechanism of Size Reduction Highlighted in Table 1 and Figure 2 · Classification and Characteristic of Size Reduction Equipments Highlighted in Table 2

Size Reduction Raw materials undergo size reduction through different mechanisms: impact, compression, and attrition. One way to classify size reduction equipment is into crushers and grinders, where grinders produce finer ...

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS François Mulenga Katubilwa A dissertation submitted to the Faculty of Engineering and the Built Environment, University of the Witwatersrand, in fulfilment of the ...

size of milling media affect efficiency of ball mill, wet grinding stirred media mills The effect of grinding media performance on milling and, In the wet grinding process of a stirred media mill the bead size, the, Read More >> ...

、、、、、、Kinoppy、DVD/CD 1,000のデータベースからをしできます。 1,500ので!

process engineering of size reduction ball milling aime; chemical engineering journal on equipment cost index; ... chemical engineering process design lecture ... The optimum composition of the makeup ball ... of the makeup ball ...

Process engineering with planetary ball mills Chemical ... Planetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of ... Chat ...

PARTICLE SIZE REDUCTION IN THE BALL MILL 83 size. Although no experimental data was presented, Garlick suggested that correct adjustment of these six variables would influence the efficiency of milling and produce ...

2017/08/07· Process Engineering of Size Reduction: Ball Milling [Linda Gong Austin] on *FREE* shipping on qualifying offers. Interesting Finds Updated Daily Amazon Try Prime Books Go Departments EN ...

Process Engineering of Size Reduction: Ball Milling: Linda . Process Engineering of Size Reduction: Ball Milling [Linda Gong Austin] on *FREE* super saver shipping on qualifying offers. ...

achieve a higher degree of size reduction compared to dry milling [6]. Dry milling is however preferred over wet milling due to the difficulty associated with the handling of a wet slurry during milling [5]. Ball mills can be used in a ...

Download and Read Process Engineering Of Size Reduction Ball Milling at local flavor mcgraw hill connect answer key business statistics dadada signing exact english visions how science will revolutionize the twenty first century ...

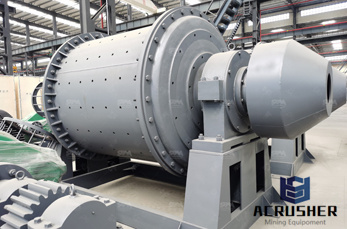

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed ...

This paper focuses on the determination of the selection function parameters α, a, μ, and Λ together with the exponent factors η and ξ describing the effect of ball size on milling rate for a South African coal. A series of batch grinding ...

Solutions in Milling Sieving Size reduction and homogenization with ball mills RETSCH Product Navigator Milling Jaw Crushers Rotor Mills Cutting Mills Mortar Grinders Disc Mills Ball Mills – MM 200 – MM 400 – PM 100 – PM 200

Process engineering of size reduction ball milling pdf Besides particle size reduction, ball mills are also widely used for mixing, blending and. The milling process takes place during rotation as a result of the transfer of kinetic energy ...

Grinding in Ball Mills: Modeling and Process . in modeling and control of the grinding process in industrial ball mills. Basic Besides particle size reduction, ball mills are also widely used for mixing, blending Get Price

READING DIRECT: 791 Manufacturing and processing 1. Introduction Mechanical alloying (MA) is a high energy ball milling process by which constituent powders are repeatedly deformed, fractured and ...

In most industries size reduction falls into two general categories: crushing and milling. Crushing typically means reducing large chunks to sizes about ½ in. to ¾ in. in diameter or smaller. Milling usually means reducing material to ...

ball mill in size reduction Ball Mill Size Reduction Plant Cost, Process Crusher. Ball Mill Size Reduction Plant Cost 290 Views. The Zenith is the professional ... advantages and disadvantages of ball mill in size reduction Ball mill and ...

2016/12/17· Process Engineering of Size Reduction: Ball Milling by R R Klimpel, L G Austin, P T Luckie starting at Process Engineering of Size Reduction: Ball Milling has 0 available edition to buy at Alibris Exclusive Holiday Coupon ...

WhatsApp)

WhatsApp)