WhatsApp)

WhatsApp)

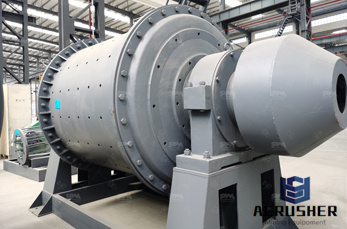

Ball mill operation and maintenance To make the ball mill operate good, we must strictly abide by the operation and maintenance procedures. Before starting the ball mill, check whether the connecting bolt, gears, couplings are ...

Horizontal mills Ball mills • Primary ball mill 1st grinding stepGrinds crushed materialUsed in cement and some mining ...

A ball mill is a type of grinder or mill used to mill the materials into fine powder in pharmaceutical industry. Read About History, Description, Parts,Construction, Ball Mill Working, Principle, Ball Mill Types, and Applications

Mill Speed Critical Speed Mill Speed No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a ...

ball mill theory pdf Pyrotechnics Ball Mill Theory Ball Milling Theory and Practice. For the Amateur Pyrotechnician. A booklet covering theory, mill construction, and milling applications by. » Learn More A Ball ...

Design Method of Ball Mill by Discrete Element. A ball mill is one kind of grinding machine, and it is a device in which ratio and using the Hertz theory of elastic contact. The subscripts i, j andChat Online Or Get Price

ball mill principle operation,theory pdf ball mill principle operation,theory pdf. ORE DRESSING. with the principles, theory, and practice of ore dressing and shall cover all the important processes ... Get Price principles of ball mill ...

theory of pedal powered grinding machine SBM mining . theory of sieving and grinding operation; theory of grinding machine; primary jaw crusher theory; theory of ... Wheat Flour Milling, Second Edition AACC International ...

Solutions in Milling Sieving Size reduction and homogenization with ball mills RETSCH Product Navigator Milling Jaw Crushers Rotor Mills Cutting Mills Mortar Grinders Disc Mills Ball Mills – MM 200 – MM 400 – PM 100 – PM 200

Ball mill A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the ...

2013/10/22· Ball Mill Working principle: When the ball mill works, motor and speed reducer transmit torque force to big and small gears of ball mill, so the barrel rotat...

Ball and Pebble Milling Theory and Practice Ball and Pebble Milling Theory and Practice ... (.pdf), Text file (.txt) or read online for free. best practices for ball and pebble milling design and operation ... Chat Online

Operating principle GG Gebr. Pfeiffer AG supplies Gebr. Pfeiffer SE The basic operating principle of the MPS vertical roller mill is Pfeiffer AG supplies MPS vertical roller mills, ball mills and moleculator mills, separators and Get ...

IV. BALL MILLS Ball mills are one of the more common mills and use a closed cylindrical container that is rotated horizontally on its axis so that the media cascades. A typical ball mill has an L/D ratio of :1. Ball mills are filled ...

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 Types of ...

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is: 2 2 3 1 bo Kd. (5) So, we have got the following: the optimal ball diameter d

leading supplier of grinding mills under the Traylor brand name since 1902 and many of the largest plants operating today have these world renowned SAG and Ball Mills ...

TECHNICAL NOTES 8 GRINDING R. P. King 82 ROOLVLRQ 5ROOLQJ ZLWK QLSSLQJ Figure Different types of grinding action by the grinding media. 7XPQEOL J 6KRXOGHU RI WKH ORDG 6WD J QDQW ]RQH J F J ...

ball mills theory pdf Hybrid Intelligent Modeling Approach for the Ball Mill Grinding Process processing industry, the ball mill grinding process is to reduce the size of the mineral concept, the perfect mixing assumption with the ...

Surfactantassisted ball milling: a novel route to novel materials with controlled nanostructure... 3 Fecht et al. (1990) [19] first described the mechanism of formation of nano crystalline materials by mechanical milling in three stages.

Dynamic Operating Regimes of Ball and Tube Mill With Varying Coal Quality An Analysis Presented By Mr. Pujari, AGM(MMD) Mr. Mohanta, (Sr. Supt, Opn) ... Outlines of The Presentation. Ball Tube Mills ...

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH ...

ball mill pipe computation and design Upload, . ball mill pipe computation and ... number of cyclones for a rod mill/ball mill. Theory ... (PDF) The Bond Ball Mill ... » Learn More The modelling of the mechanical alloying ...

ball mill operation manual Grinding Mill China ball mill operation and maintenance manual pdf. BinQ Mining Equipment ball mill operation and maintenance manual pdf, operation maintenance of a ball mill pdf, ball Read More

WhatsApp)

WhatsApp)