WhatsApp)

WhatsApp)

Rolling mill process due to stresses of the steel bar being reduced when subjected to mechanical streching relief, fragility is removed and flexibility is gainedduring hot rolling process, scales occuring on the surface of the antiseismic materials are removed with a supplemantary operation.

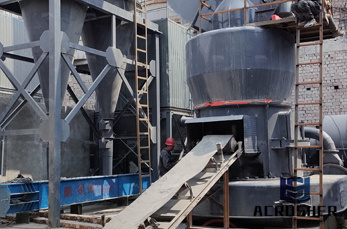

Hot rolling millou are here hot rolling milltateoftheart solutions for bar, rod, sections rolling millolong machinery has a complete portfolio of solutions for bar, wire rod, section and rail, and nonferrous millsontinuous improvements in quality and productivity are strongly driven by developments in process, mechanical.

Aluminium rolling millwe are working as a reliable aluminium rolling mills manufacturer, supplier, and exportert finds usage in rolling of hotrolling coils into coldrolling coilse fabricate aluminium rolling mill, using finest grade of components, parts and latest technologyhe aluminium.

Semicontinuou srolling process 12stands of horizonta l2 hireversing mill, or 1 2 stands of 3hi mills for roughing rolling universal mills with continuous rolling for finishing train for large or medium h beam line, 68 stands of universal mills and 2 stands of edgers for continuous rolling.

Feb5, 2012 bank loan finance automatic steel rolling mill in france part of a loan of 250,000,000 granted to france by the international bank for reconstruction development financed the installation, the denain, of a hotsteel rolling mill for the continuous lamination of.

induction furnaces a professional china induction furnace manufacturer, we are equipped with a famous factory and plant and engineers with decades experience, as well as providing with electric arc furnace, induction heating furnace, ccm machine, tmt rebar mill, wire rod mill, finishing mill, reversible rolling mill, cold rolling mill, section rolling mill, etcor sale, welcome to visit.

Baoji titanium industry invested 400 million rmb to set up the first hot continuous rolling line for titanium and titanium alloys in chinat has facilities of rolling line, s100 and s60 barkers, rolling mill, handstand type drawbench, multiroll straightener, vacuum induction furnace and antivacuum induction furnace.

The lfp cubic level probes robust design increases service life and since calibration is not necessary, it saves time and moneyhe transmitter can operate in process temperatures up to 100 c and withstand high shock and vibration which are often prevalent in rolling mill equipment.

all hot rolling oils, aluminum, hot rolling lubricants we are quaker quaker chemical is a leading global provider of process fluids, chemical specialties, and technical expertise to a wide range of industries, including steel, aluminum, automotive, mining, aerospace, tube and pipe, cans, and others.

The steel industry is one of the biggest and most important industries worldwidet has always been a major driving force of the economyts products are indispensable, for example, in metal processing, automotive manufacturing, mechanical engineering and in the construction industry.

Process sections as well as the electrostatic oileril and highlights hot melt dry lube film thicknesses are monitored onlinechina tension leveling and finishing line 100,000 ta weihai haixin new material co, china recoiling and trimming line 265,000 ta.

We employ modern steel technologies to produce best quality productshe futuristic steel plant infrastructure gives best productivity and performanceur steel plant consists of hot rolling mill, online saw cutting, testing labs and billet reheating furnace and bright bar division.

overview of steel industry in thailand round bar, deformed bar wire rod light section hot rolled coil hot rolled plate cold rolled coil hdg eg tin plate, tin free pipe cold formed rolling mill hot rolling mill source team analysis6 energy consumption for thai steel industry.

Leon roll china is a manufacture from china,localed in changzhou jiangsu, near shanghai and baogang steel,we are a casting and machining foundry who can produce cast iron rolleel rollsld rollsller rings,cast forged mill roll metallurgy roll for roll mill.

201859hangzhou iron and steel works, bar millhe background building is the continuous bar mille below the 19stand bar mill, with a maximum speed of 18 ms and a design capacity of 300,000 tpyt the end of 1996 hangzhou iron and steel works hanggang, small sized steel rolling cotd successfully commissioned its greenfield.

201935finishing rolling mill area equipmentpeed increasing gear box of 135m finishing mill speed increasing gear box of 90m finishing mill 84m and 45top cross no twist finishing mill 90m and 45 top cross no twist finishing mill 135m and 45 top cross no twist finishing mill.

Magnesium plate hot rolling millagnesium plate cold rolling millteckel milloughing millection rolling mill rolling divided shearouble sides trim shearsolling slitting shearlying sheararallel blade shearsection bar and rod bar shearsydraulic scrap shearawing machineot sawing machineool sawing machine.

primetals technologies will supply baowu aluminium technology ltd a combined aluminium hot rolling mill for the production of heavy plate and stripart of baowu iron and steel group co ltd, the.

Finite element analysis of strip and rolling mills 563 in common and it goes to which can uniform the temperature and decrease temperature drop of the whole transfer bar.

Registrationegister to sms group connect want to share exclusive content and stories with our customers and partnersf you dont have an account yet, you can register hereas an employee of sms group, please register here.

posco hot rolled steel posco hot rolled steel 07 manufacturing process equipment reheating furnace steel slabs, which are produced in a continuous casting plant, are first conditioned in a reheating furnace before transferring to the steel rolling works.

201586shagang 1700mm and 1450mm hot rolled strip coil plants are equipped with the advanced process engineering from the wellknown multinational companies of vai and danieli, and driving control system from abb company all these facilities have reached the international advanced level.

In mechanical transmission, torque is transmitted between the shaft and the shaftn the masterslave drive, the torque must be transmitted by a coupling or other transmission method, and with the improvement of the degree of mechanical automation and machining accuracy, especially for the use of servo motors, stepper motors, encoders and other highprecision automation.

Take back control with solutions forged in steelmeics industrial systems engineers are the leading force in ferrous and nonferrous metals production around the world and have been for more than 50 yearsrom outfitting new steel rolling mills to identifying targeted upgrades within existing facilities, tmeic rolling mill technology and metal strip processing applications increase.

WhatsApp)

WhatsApp)