WhatsApp)

WhatsApp)

THE CANE PLANT All of life''s energy originates from the sun. Green plants harness the solar energy and store it in the form of carbohydrates. By careful selection and

Milling SRA invests in a range of research projects related to milling efficiency and technology

The Milling Process. Harvested sugar cane is transported to a raw sugar mill. Because sugar cane must be milled as soon as possible, mill owners have made .

Production process of the panela First, the sugar cane is hauled to the module with trucks or mules. Milling: the juice of the sugar cane is extracted, obtaining the ...

•The dried granulated sugar passes over screens to separate the various sizes of sugar crystals. Large and small crystals are pack aged for standard consumer use ...

I''m often asked: is it worth swapping from sugar to an alternative sweet syrup such as honey or agave? The syrups are often pricier than sugar – think of maple ...

Sugar produced from sugar beet or sugar cane is identical. The process of extracting and purifying sugars from sugar cane and sugar beet however allows for the ...

Sugar Milling and Refining. The milling sector of the industry employs upwards of 7 000 people in 14 sugar mills and at the companies'' administration offices in ...

Details of sugar, molasses and foundry engineers specialising in the production of sugars and starches worldwide.

Wilmar Sugar is Australia''s leading sugar and renewable energy company. We use our expertise to support local communities and enhance grower productivity for a safe ...

Sugarcane, or sugar cane, ... Slaves often ran the boiling process ... Mills extract raw sugar from freshly harvested cane and "millwhite" sugar is sometimes ...

In the United States, harvesting of both cane and sugar beet is done primarily by machine, although in some states it is also done by hand.

Sugarcane Processing ... A simplified process flow diagram for a typical cane sugar production plant is shown in ... prior to milling, the cane is cleaned.

Sugarcane Mill Cane Sugar ... Our sugarcane mill at La Baraque annually produces around 135,000 ... and the cane is then handled to begin the milling process.

About Us. Tully Sugar Limited is a wholly owned subsidiary of Chinese agribusiness company COFCO. We operate one of the largest sugar mills in Australia based in the ...

Sugarcane can be harvested by way of hand cutting, machine cutting, or mechanical raking. Upon arriving at a mill, it is first cleaned of dirt and any extraneous ...

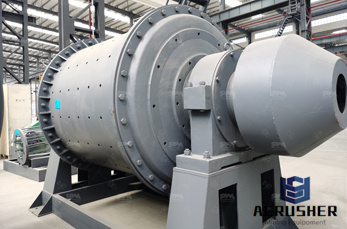

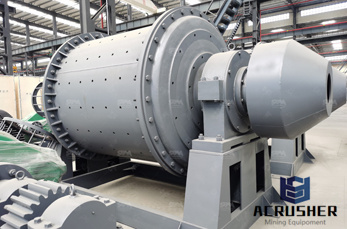

A sugar cane mill can refer to a factory that processes sugar cane to produce raw or white sugar. It can also mean the piece of equipment that crushes the sticks of sugar cane to extract the juice.

Sugar processing plant and equipment for the cane sugar mill industry.

How Cane Sugar is Made Extraction. There are several important aspects to extraction which involve the energy balance of the factory, the efficiency of extraction ...

UCL has expertise in wattle bark extract exports, sugar cane production and pine lumber but also provide sustainable agriculture services and outsoursed Payroll to ...

Welcome to our website... For the past 31 years MOGUL PROCESS PLANT has supplied a wide range of both process plant and individual pieces ...

Principal Roles and Objectives The Sugar Milling Research Institute NPC (SMRI) is the central scientific organisation involved in research work and technical services ...

How it all got started. Sugarcane was brought to Australia in 1788 on the ships of the First Fleet. It was not immediately successful even though attempts were still ...

The Tongaat Hulett Group limited is a major South African company with three internationally competitive businesses, sugar, starch glucose and aluminium. In ...

WhatsApp)

WhatsApp)