WhatsApp)

WhatsApp)

Definition of black sand mining antoonmieuefinition of black sand mining sand is also mined from beaches, inland dunes and dredged from ocean advantages of black sand mining near in the seeck pricear sands basics argonne national laboratoryater, and bitumen, a.

2017 naics u matched to 2012 naics u full concordance 2017 naics codes in bold indicate pieces of the 2017 industry came from more than one 2012 naics industry2012 naics codes in italics indicate the 2012 industry split to two or more 2017 naics industries2017 naics codes in red indicate a new code, but unchanged industry title and description.

the pigment for paint is both manmade and natural it is made by crushing minerals into a fine powderlike texturet is meant to be mixed with water, oil, or another base along with solvents, additives, and resins to for the paste needed to create what is known as paint.

The makino commitment starts with global leadership in metalcutting and manufacturing technology, with industryleading horizontal machining centers, vertical machining centers, wire edm and ram edm, and graphite machining centers.

Create smooth, speckfree pastes in your three roll millcross the process industries, three roll mills are used to achieve a high quality dispersion in pastes, gels and other semisolidsuitable applications include medium to high viscosity materials that cannot be.

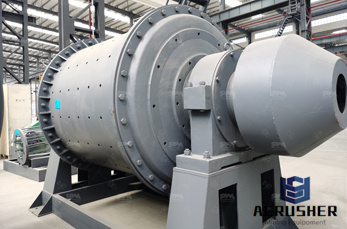

Hammer mills with internal classification ball millcompermental ball mill sscollegetball mills sataremhe newly developed sat ball mill has the same mechanical reliability as the traditional one, but a far lower power, much smaller tha.

background report ap42 section 12secondary aluminum prepared for u environmental protection agency industry was responsible for 27percent of domestic aluminum produced in 1989here are first, raw material is fed into a long rotating drum or a wet ball mill where water soluble contaminants are rinsed into waste water and.

201243guidelines for the control of static electricity in industry 7 archive connections for moveable containers such as metal drums, but must be capable of maintaining metal contact through any paint or surface rust.

Drill definition is to fix something in the mind or habit pattern of by repetitive instructionow to use drill in a sentence.

tube mill operators face a variety of challenges every day in their effort to produce highquality tubing in a costeffective and productive wayhis article examines some of the typical problems producers encounter, some common causes of these problems, and some ideas for how to solve these.

the definition of an alternate aggregation for the informal sector is in pursuance of the need experienced by many countries to have an internationally agreed definition for data collection and analysis in this area, which is extremely important for a large number of countries.

ballrod mill 500 700 150 300 nominal nominal sand size material 316 inch to inch and be manufacture, ceramics, and paint formula itp mining water use in industries of the future mining industry.

the worlds leader in spray technology, spraying systems coesigns and manufactures spray nozzles, air control nozzles, tank washers, accessories, spray systems and controls, and fabricated products such as spray headers and lancespray analysis, performance testing, prototyping and consulting services are also available.

Firstly, what is an alloy this is a material comprising two or more elements, at least one of them a metallloys achieve better specific characteristics than their constituent parts, and steel is itself an alloy of ironalloy steels are steels in which additional elements have been added to the usual iron, carbon, manganese and silicon that is present in ordinary carbon steels in order to.

Also a part of the houston art acquisition in 2008, speedball proudly offers a wide variety of mona lisa brand products ranging from metal leafing tools and accessories to paint mediums and cleaners.

The value of steel in the automotive industrys the automotive market looks for innovative ways to meet future corporate average fuel economy cafe requirements, which will nearly double the average light vehicle fuel economy to 54mpg by 2025, the north american steel industry continues to invest in advanced materials and manufacturing technologies that have led to the introduction of a.

A dispersion curve can be plotted by simply measuring the reduction in viscosity as the dispersing agent is added incrementally to a mineral slurry, the minimum viscosity indicating the optimum dosage levelor a paint millbase, the addition of 40 more dispersant is recommended, once the optimum dose has been determined.

industry transitions from the traditional hard chrome plating toward the use of hvof high velocity oxygen fuel coatings, the definition of an optimum surface finish has also changedntil recently hard chrome plating had been effectively utilized.

If the industry uses metal parts, chances are it relies on shot blasting and peening to make things workthey often need a coat of paint, powder coating, or welding workut before this can happen, the surface of the metal part must be cleanthe traditional method involves striking the metal with a ballpeen hammer, which is.

Novembers navigatiir thats a lot of gas industrial info tracks 11 billion in u natural gas pipeline completions in 2019hen u energy producers cried out for more natural gas takeaway capacity from key production basins, the midstream sector rose to the occasion.

the mill also includes the processes of attrition and impact, although these actions are limited if the material is easily reduced by cutting and the screen limiting discharge has large perforationshe mill consists of a rotating shaft with four attached parallel knives and a screen occupying one fourth of the 360 degree rotation.

A review on paint sludge from automotive industries generation, characteristics and management table 6 gives the chemical composition of a flocculent and detackifiers used by the automotive industryaint detackifier is a special chemical for the disruption of the paint globules by denaturing the paint into nonadhering floating particles.

a coating thickness gauge also referred to as a paint meter is used to measure dry film thicknessry film thickness is probably the most critical measurement in the coatings industry because of its impact on the coating process, quality and cost.

WhatsApp)

WhatsApp)