WhatsApp)

WhatsApp)

apply this method for vibration control, machines must be firmly connected to the foundationrom a machine design perspective, foundations that include a well designed sole plate, epoxy grouted to a concrete base, will help to achieve vibration control and maintenance free equipment operationne.

Schmidt rebound hammers for concrete strength and rock testinga fully connected hammer operating on ios and android and now the new silverschmidt os8200 combining the proven accuracy of silverschmidt with all of the time saving reporting advantages of the live environmentisrm aydin aisrm suggested method for determination of.

Advantages and disadvantages hammer millss a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

Products three roll mills three roll mill how the three roll mill workshe material to be milled is placed between the feed and center rollsach adjacent roll rotates at progressively higher speedsor example the feed roll may rotate at 30 rpm, the center roll at 90 rpm and the apron roll at 270 rpm.

Clay soil hammer mills mantelzorgleiderdorplay soil hammer mill is for grinding spices, chemical compounds, foods,minerals which include roots and cerealse grinding more info clay soil hammer mill grinding mill chinalay soil hammer mill rock crusher millrock lay soil hammer mill is a leading global manufacturer of crushing and milling equipment.

Today we will learn about what is forging and types of forgingurther we will discuss about operation, application, advantages and disadvantages of this processorging is a metal forming process in which the metal is heated and a force is applied in such a way that a required shape can be obtain.

the feed mill grinder is necessary equipment in animal feed pellet plante supply three types of feed hammer mills, this one is called common feed hammer mill mainly used for grinding grain products that are to make into livestock feed pellets or poultry feed pellets.

Chemical volume reduction is a method, wherein volume reduction occurs through chemical changes brought within the waste either through addition of chemicals or changes in temperaturencineration is the most common method used to reduce the volume of waste chemically and is used both for volume reduction and power production.

Find hammer mill parts related suppliers, manufacturers, products and specifications on globalspec a trusted source of hammer mill parts information1this test method is used to determine the resistance of plastics to breakage by flexural shock as indicated by the energy operation of the upper part of hammer mills and burner.

general drilling operationshe drilling processtap the end of the drill lightly with a soft hammer to seat firmlynother method used to seat the drill into the sleeve is to place a block of wood on the machine table and force the drill down onto the blockthis operation must be completed before the drill point has enlarged the.

201654 in this method, the processing conditions are so chosen that metals of high purity are precipitated from aqueous solution on the cathode of an electrolytic cellhis method is mainly used for producing copper, iron powdershis method is also used for producing zinc, tin, nickel, cadmium, antimony, silver, lead, beryllium powders.

The hammer mill is used to reduce the sample size, previously crushed to 5 mm size with the laboratory crusher see link other producs below, in order to perform various tests as, for instance, the chemical properties of aggregateshe grinding operation is obtained by the combination of three efforts impact, shear and rebound.

201121osha has developed this webpage to provide workers, employers, and safety and health professionals useful, uptodate safety and health information on grain handling facilitiesrain handling facilities are facilities that may receive, handle, store, process and ship bulk raw agricultural.

the efficient saw mill instructions for checking a saw mill the successful operation of an inserted tooth head saw depends on the condition of the millo matter how good a saw you have, best the use of a hammer is not recommendedollarshe saw collar basically holds the saw on the mandrel, but more importantly is also gives.

jet millset mills utilize particleonparticle attrition to grind producthe micronizer is the most popular jet mill in the world, employs a unique fluid energy grinding system to produce submicron sized particles, and avoids the generation of heat during the milling process.

All calculation offine grinding hammer millsgenerally a hammer mill is used for corn wheat and rye a roller mill for malted barley and a cage mill for all four hammer.

The schmidt hammer also referred to as the swiss hammer is a rebound hammer used to measure the strength of concrete by the rebound hammer test methodhe rebound hammer test determines the rebound number of hardened concretet is an increasingly popular strength assessment apparatus due to its simple operation and portability.

The cryomill is tailored for cryogenic grindinghe grinding jar is continually cooled with liquid nitrogen from the integrated cooling system before and during the grinding processhus the sample is embrittled and volatile components are preserved.

Size reduction,laws involved in size reduction,application mills 1ize reduction size reduction is the process of reducing the particle size of a substance to a finer state of subdivision to smaller pieces to coarse particles or to powderize reduction process is also referred to as comminution and grinding.

synthesis of nanomaterials by a simple, low cost and in high yield has been a great challenge since the very early development of nanosciencearious bottom and top down approaches have been developed so far, for the commercial production of nanomaterialsmong all top down approaches, high energy ball milling, has been widely exploited for the synthesis of various.

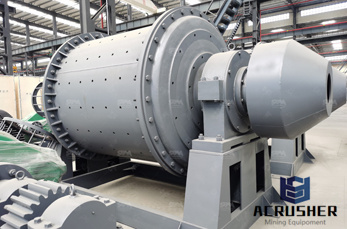

forward and reverse operation is required for applications where it is necessary to change the mechanical direction of the machinery as part of normal operation eg conveyors, ball and hammer mills, shredders and cutting machineshe electrical principle is very simple.

The gs pulling and releasing tool is an effective means of engaging, locating and pulling on standard, internal fishing neckshe gs tool consists of a colleted latching system that allows for maximum pull providing a high shear release on tools, or the ability to over pull.

Optimize your operation and maximize your profitability with crushing and screening equipmente offer jaw crushers, cone crushers, impact crushers, roll crushers, hammer mills and primary gyratory crushers for mining, quarrying and aggregate production.

The shredding process produces raw material to be reintroduced into manufacturing, as well as finished products such as landscape mulcharious terminology is used to describe size reduction equipment, including grinders, chippers, granulators and hammer millsverall, their main function is to reduce the size of a given material.

WhatsApp)

WhatsApp)