WhatsApp)

WhatsApp)

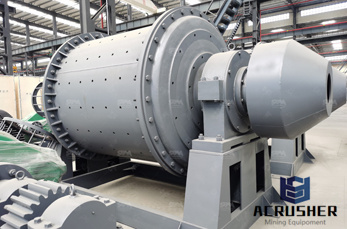

A ball mill is a type of grinder used to grind and blend ... Ball mills are used extensively in the mechanical alloying process ... Cement mill; Vertical roller ...

Cement ball mill for constructing procedure,cement grinding. chemical,Cement mill is mainly used to grind the clinker and raw materials in cement industry and also ...

In our entire turnkey cement plant equipments and machinery, we supply ... Cement Plant Process Equipment ... Ball Mill Manufacturers: As a ...

A cement mill (or finish mill in ... are now increasingly popular as a "pregrind" process, with the cement finished in a single chamber ball mill. This gives good ...

CHAENG | Great Wall Machinery provides you:Slag Grinding Plant,Cement Equipment,Vertical Mill,Ball Mill,Rotary Kiln For Quarry, .

Metallurgical Content1 RAW CEMENT GRINDING2 WET VS DRY Grinding of Cement3 CLINKER GRINDING4 Cement Grinding Mills5 High Efficiency Cement Grinding Mill .

Cement mill is also called cement ball mill, which is mainly used for grinding cement clinker in the cement production process. It is one of the important cement ...

Grinding in Ball Mills: Modeling and Process Control ... cement production, chemical ... The design of a ball mill can vary significantly depending on the ...

Cement gas separator is to point to in the process of use separator cement ... impact crusher,ball mill,Cement Air Separator and other equipments used in ...

ball mill process control, modeling and control of cement . modeling and control of cement Grinding processes, ball mill process control

Cement ball mill is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in ...

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling ... process Tip of

Advanced process control for the cement industry ... provides advanced process control and optimization for cement plants, ... Ball Mill Application

cement mill optimization. i have a polysius ball mill with capacity 110 tph. normally i get blaine at mill outlet around 200 while my product blaine target is 400 .

CEMENT GRINDING OPTIMISATION ... The electrical energy consumed in the cement making process is in ... The basis for modeling the twocompartment ball mill is the ...

Ball mills Outotec A ball mill grinding circuit is a ... Modeling for the ball mill grinding process is still an imperative but ... cement mill internal parts ...

Cement grinding process,Vertical roller mills and ball mills . Around 110 years ago a Danish engineer, M. Davidsen, patented a pioneering invention in France which ...

Sep 07, 2016· re cement ball mill . Hi, What is the maximum of the clinker size entering first chamber? What is your damper percentage at the mill .

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

CEMENT MILLS Twochamber ball mills for the cement industry ... If the process material is moist, cement mills can also be confi gured with a ... the cement mill can

ball mill flow process. ... Process Diagonistics Studies for Cement Mill fundamental process used by ball mills in FGD systems to produce line ...

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill ...

Closed circuit systems for ball millsCosts Benefits . ... for 5000t/d cement production line using a ball mill with closed circuit system, ... Parent Process:

WhatsApp)

WhatsApp)