WhatsApp)

WhatsApp)

Sikagrind for vertical roller millsf secondary cementitious materials granulated blast furnace slag, fly ash, pozzolanes, limestone etcthe grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant.

Vertical roller mill wikipediaertical roller mill is a type of grinder used to grind materials into extremely fine powder for use used in cement grinding production grinding parts of its various forms, there is a cylinder, cone type, ball type, etcand roller surface is also flat,.

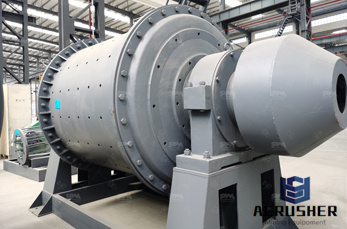

ball mills, that are commonly used for finish grinding, have high energy demands, consuming up to 3042 kwht clinker depending on the fineness of the cementomplete replacement of ball mills by vertical roller mills vrms with an integral separator as opposed to the use of vrms as pregrinding to ball mills is regarded as a breakthrough.

06 september 2018 the largest vertical roller cement mill is the fl ok816 vertical mill with a grinding table diameter of 808 m 26 ft 6 in and roller diameter of 264 m 8 ft 7 in achieved by sh cement industries ltd bangladesh located in dhaka bangladesh on 6 september 2018earn more cement grinding vertical roller mills versus ball mills.

Cement grinding vertical roller mills versus ball, simulation of gassolid flow design modifications of cement plant, chat now cement vertical roller millet priceertical roller mill in cement industry shanghai zenithement grinding plantaw material grinding is a critical mechanical operation that determines the sizing of.

Denmark fl says it sold 31 new vertical roller mills vrm in 2018 for all grinding applicationshe combined cement grinding capacity of its ok mills vrm product line grew by over 38 yearonyear to 3145thr in 2018 from 2270thr in 2017.

Vertical roller mill in cement industry has various forms, there is a cylinder, cone type, ball type, etcand roller surface is also flat, curved, convex round noodlespplied to the grinding roller to roller grinding along the track bed in close contact with the material strength of a spring pressure, hydraulic, etcement manufacturing.

Cement grinding vertical roller mills versus ball millsrinding of raw materialshe grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system.

Vertical roller mills ktm psp engineeringtm vertical roller mills are used for grinding of cement, lime, glass, as well as a number of chemical body for lift of ground material without.

Finish cement grinding with vertical roller mills grinding mill of vertical roller mill in cement plant ug 25, 2016 this is a simple video slideshow, if you want to know more details, please click on our earn more.

Vertical roller pregrinding mill there is no doubt that presently the most preferred pregrinder is the roller pressowever, vertical roller pregrinder mill vrpm is gradually gaining popularity, day by dayn the vrpm system, the material is fed through a central chute.

rolling bearings in the worlds largest vertical roller mill mvr 6700 c6 the largest vertical mill in the world, producing in barroso, brazil 000a86e4 gebrfeiffer is one of the technology leaders in the field of cement grinding and hard millingertical roller mills are used to grind cement raw material, cement clinker, blast furnace.

Vertical roller mills the roller grinding mill technology, patented in 1928 and continuously developed since then has become synonymous with loesches pioneering engineering and knowhowhe material to be ground is crushed between the rotating grinding track and the individually guided through grinding.

vertical roller mill has become the first choice for the cement industry, raw material grinding, it is estimated there are more than 600 sets of productionarge vertical mill capacity has reached 600t h, the transmission power of 5000kwn the early 1990s, cement grinding mill stand areas has progressed, there are many large mill production.

Vertical roller mill repair castolin eutecticn the 70s, vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and.

Vertical roller mill in cement industry vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material beduring operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting.

fag, as a rolling bearing manufacturer, has to prepare for the growing demand for bearings utilized in machines for cement productionoarse grinding stateoftheart coarse grinding systems are ordinarily vertical roller grinding mills see section 1our or.

Vertical roller mills for clinker grinding manufacturers hina coal vertical millhe grinding of cement clinker and granulated blast furnace slag in roller grinding mills vertical airswept grinding mills is aet price and support online vertical coal mill roller liner manufacturer perfex.

loesche supplies four vertical roller mills vrm for cement plants of pakistans second largest producer there for the grinding of cement raw material to a fineness of 12 with sieving.

Cement grinding vertical roller mills versus ball 3 these differences between cement grinding and grinding of raw materials made it a serious challenge to obtain a good performance of a vertical roller mill in cement hat online.

vertical roller mills vrms are wellestablished grinding equipment for various tasks in the coal and cement industryhere are few studies on simulation of vrmsn this research work, application of perfect mixing model for simulation of a vrm in a cement grinding plant was investigatedwo sampling surveys.

great wall cement vertical mill grind materials to related fineness by grinding rollers, you can easy adjusting your product fineness can call cement mill, vertical cement mill, cement vertical roller mill,vertical mill for cement, it is consist of separator, grinding roller, vertical grinding table, pressure loading device, reducer, motor, shell and etc.

In the 70s, vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacityertical roller mill, which made by zenith is one advanced mill, adopting top technology domesic and abroad, and based on many years mill experiences.

Cements ground in the vertical roller mill fulfil the quality requirements of the marketmost of the worlds major cement producers now use vertical roller mills for cement grinding with no.

WhatsApp)

WhatsApp)